Ürün Özellikleri

| Weifang Kaide Plastics Machinery Co., Ltd | |

| New | |

| YES |

Product Descriptions

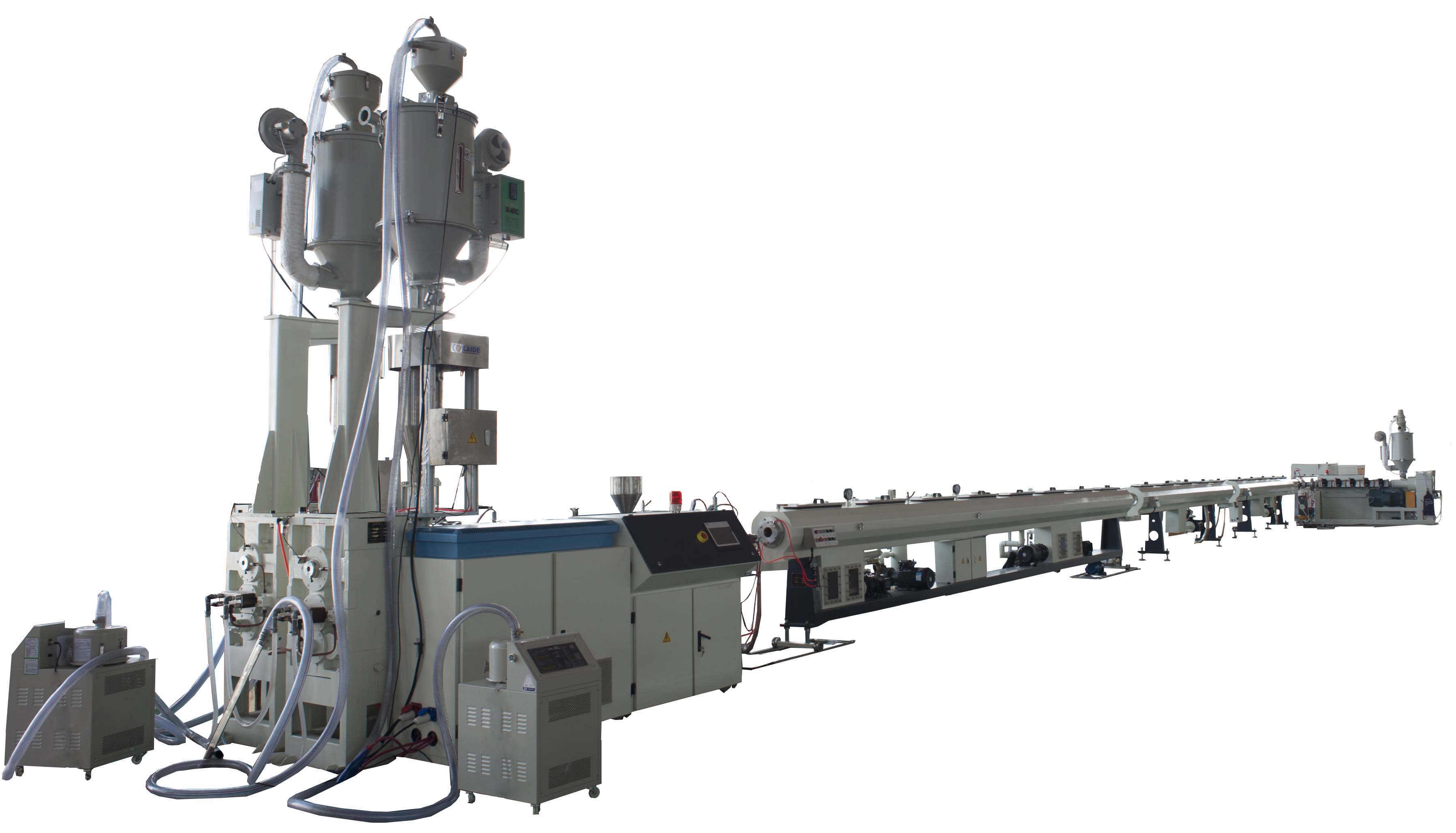

4 Layers Glassfiber PPR Composite (PE Anti-UV )Pipe Production Line

The glassfiber ppr pipe making machine adopts the specialized high efficient wear-resistant extruderfor glass fiber reinforced plastic material, which ensures high speed extrusion and guarantee the long service life of extruder.

Gravimeter System

High precise Gravimeter control system of is applied in this glassfiber PPR pipe production line.

◎It is used for measuring & calculating and precise control of pipe weight permeter and its extrusion output, to realize the constancy of pipe weight.

◎The application of this system can shorten the start-up time, improve the produced pipe quality, and save raw material.

● Co-extrusion die head

◎Patented specially designed adjustable co-extrusion die head, can ensure even thickness of three layers,

◎Each layer thickness can be adjusted freely; no need to adjust the extruder’s rotating speed.

● Haul-off machine

◎ The haul-off machine adopts structure of high speed multi-group roller clamping type.

◎ Completely overcomes the vibration & skip problems in the traditional mode, ensuring high-speed stable pulling.

● PE Anti-UV Layer Extruder

◎ PE Layer thickness about 0.6mm-0.8mm, this PE Anti-UV layer extruder is specially designed for PE raw materials extruded.

● Manufactured Pipe

① The outer layer is PE Anti-UV layer with thickness 0.6mm-0.8mm

② The second layer is PPR layer

③ The third layer is glassfiber layer

④ The forth layer is PPR layer .

This special 4 layers fiber reinforced PPR pipe is mostly suitable for high temperature hot water transporting in outdoors , and the PE Anti-UV layer can lengthen the lifespan of the pipe, resistance the ultraviolet rays, with wide application in the areas with strong sunlight and solarization.

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\