Product Specification

| Brand | AMF Rose |

| Condition | New |

| Warranty | YES |

| Power Source | Electric |

Product Descriptions

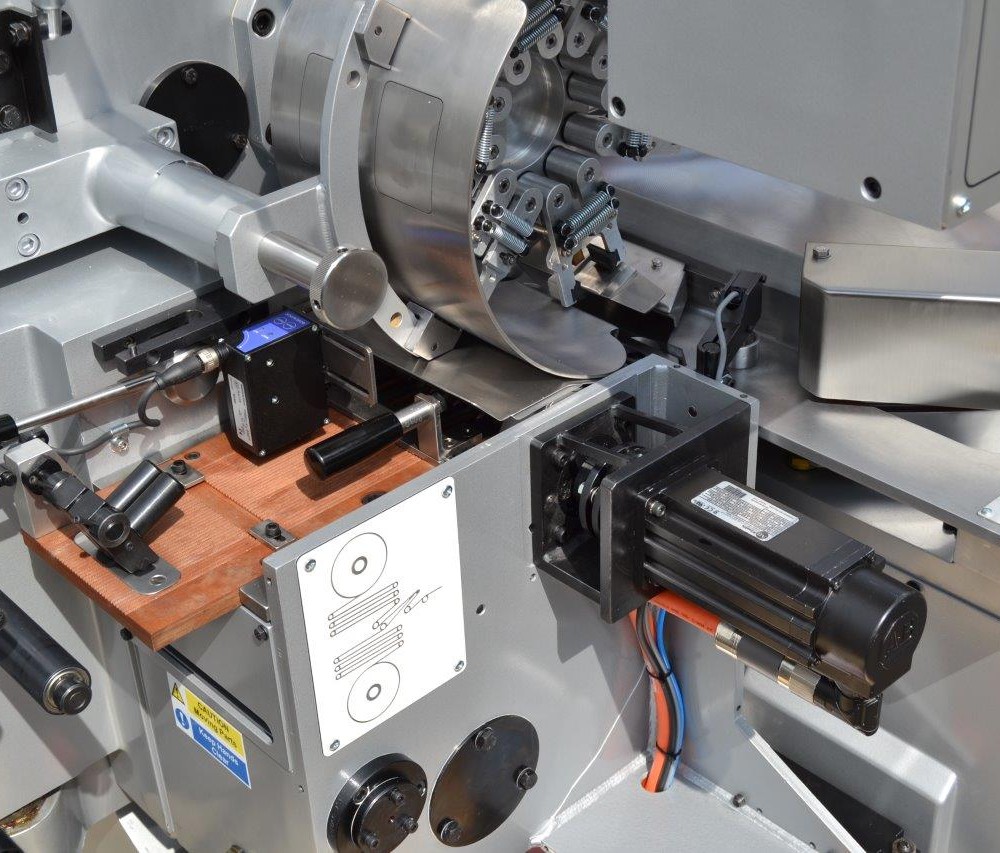

The ‘7IST’ is a versatile double twist wrapping machine used to wrap a wide variety of pre-formed sweets including solid and centre-filled high boiled lines, die-formed and deposited toffees, chocolate balls etc, in double-end twist style.

Benefits of the double twist wrapping machine are its ability to handle variations in product size and shape, and the speed and simplicity of change-overs from one product size to another. Operator convenience, ease of cleaning and maintenance, and safety factors have been incorporated into the design.

Features

Automatic operation

The double twist wrapping machines require minimal operator intervention – one operator can attend to multiple machines. Alternatively, fully automatic delivery systems can be provided to feed sweets from the down-stream production machinery to multiple wrapping machines.

A level sensor located above the feed disc ensures that the vibrating candy feed tray operates at the correct time to optimise the feeding of product. A no-sweet-no-wrapper mechanism ensures that paper wastage is kept to a minimum. An optional automatic paper splicing unit can be provided if desired.

Servo-driven paper feeding system

The 7IST double twist wrapping machine uses a sophisticated paper feeding system, which is driven by a servo motor. This minimises the mechanical parts and ensures very accurate paper cutting and minimal wasted paper. Changes in paper length are done simply through the operator panel, thereby avoiding the need to change paper length gears. Should the paper feeding roller become worn after a period of use, the intelligent software can be simply re-programmed to accommodate this wear and still provide the correct wrapper cut-off length.

When using registered wrapping material and photocell system, the operator can simply load a new reel and press the ‘measure’ button on the HMI – the machine will automatically feed and measure the paper, and store the exact cut length between the registration marks.

The HMI allows numerous pre-set recipes to be stored, which can be quickly and easily retrieved by the machine operator.

Output

- Up to 650 p/m

Size Range

Length: 16 – 35mm

Width: 13 – 19mm

Thickness: 6 – 17mm

Diameter (round shapes): 16 – 29mm

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\