Product Specification

| Clextral Machinery | |

| New | |

| YES | |

| Others |

Product Descriptions

Our twin screw extrusion processes for Food & Feed production are flexible and allow you to easily and quickly respond to market changes. We develop additional food processing equipments that fit extrusion lines to extend the range of products and offer the novelties consumers are constantly looking for. These technologies are either supplied with our conventional production lines right from the beginning, or can be proposed as “complementary upgrading kits” to be installed on existing lines.

For example, by installing a co-extrusion kit a breakfast cereals producer can diversify his offer with filled products or a pet food manufacturer can process attractive bicolor pet treats.

Examples of additional technologies to upgrade Clextral lines :

Co-extrusion

filled pillowsCo-extrusion is a 2-in-1 step process allowing to obtain in a single production run a product combining two distinct characteristics : a crisp cereal based envelope and a sweet or savory filling. Co-extrusion uses the extruder to create the outer shell directly expanded, while an auxiliary system allows simultaneous injection of a filling at the die level. The production line can then process filled or unfilled products.

Bi-coloration

bicolorationThe bi-coloration is a technology that allows on a single platform to manufacture products with two colors which are clearly identified in the mass, possibly also with two different textures. Our bicoloration kit is fitted to existing production lines.

Inclusions

inclusionsConsumers are demanding more healthy products with natural and genuine appearance. Clextral has developed a patented technology that allows the integration of solid inclusions greater than 0.5 mm in expanded extruded snacks.

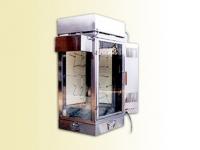

Laminating and stretching unit

IMG_71622 Laminating and stretching is a process consisting in shaping the extruded material by squeezing and stretching it between two cylinders. This technology generates unique texture through post extrusion treatment, and is particularly useful for manufacturers of flat breads, crispy cookies and co-extruded products.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\