مواصفات المنتج

| الماركة | Canon |

| المادة | Others |

مواصفات المنتج

Benefits

Maximum productivity irrespective of content, ink coverage or media

Fully integrated end-to end workflow with simultaneous unloading and printing

Versatile media handling

Good quality Instant-dry prints

6 rolls for 1200 metres input capacity

Easy to use operator interface supports unattended and automatic delivery of finished output

Fast predictable processing in end-to-end PDF workflows with Adobe PDF Print Engine 3 (APPE3)

Enhanced security features with Windows 8 embedded controller

Detailed Benefits:

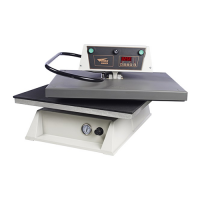

Exceptional productivity

The Océ ColorWave 810 is the ideal, cost effective replacement for mid volume B&W production printers, consistently delivering impressive results and quick turnaround times. Using extensively proven Canon technologies, five print heads fire over 3 billion drops of ink every second from more than 350,000 nozzles to cover the full 106 cm (42 inch) width in one pass.

Flexible media handling

Océ ColorWave 810 employs a 6-roll media input module and, with rolls up to 200 metres in length, offers 1,200 metres of input capacity. The input module handles widths from 297 mm to 1,067 mm (42 inch) and a wider range of media types including coated and photo papers, film and self-adhesive papers. The system automatically switches from one roll to another when it’s empty or when another media type or size is required.

Extensive applications

A four colour system uses 5 aqueous dye, 2 litre ink tanks, including two blacks for higher optical density, and prints at 1600 x 1600 dpi, with a droplet size of just 1.2 picoliters. The high image quality with fine lines and sharp text makes the Océ ColorWave 810 perfectly suited to an extensive range of applications, from posters and point of sale to maps and technical documents. Support for Grayscale printing enables B&W print outs for a more diversified pricing strategy.

Easy-to-use operator interface

A large, bright and easy to use interface panel simplifies production management for every level of operator and supports the unattended and automatic delivery of finished output. Operators can monitor printer status, edit jobs, manage print job queues and address the different folding requirements of customers with ease thanks to embedded folding templates. The ripping and submitting of complex files and multipage PDF files is quick and easy thanks to the Windows 8 embedded controller with enhanced security features and Adobe PDF Print Engine 3 (APPE3).

Fully integrated workflow

A range of fully integrated finishing options is available to support seamless end-to-end document workflow and allow the operator to fully capitalise on the print speed – delivering ready-to-use printed output with quick turnaround. These include an Océ Estefold 5011/5013 folder (ideal for CAD-GIS production) and the Océ Dual Tray High Capacity Stacker (ideal for poster production), which uses two large delivery trays, so unloading and printing can take place simultaneously for maximum uptime. Prints come out dry and are immediately ready for finishing and delivery.

طريقة دفعة آمنة وموثوقة باستخدام منصة عبرة للدفع عبر الانترنت

طريقة دفعة آمنة وموثوقة باستخدام منصة عبرة للدفع عبر الانترنت  \

\