Product Specification

| Brand | Clextral Machinery |

| Condition | New |

| Warranty | YES |

| Mechanical Condition | Others |

| Fuel Type | Gasoline |

Product Descriptions

Process efficiency

Ingredient flexibility to process a wide variety of :

Outer parts with various cereal grains and granulations : wheat, rice, corn, barley, rye, oats, buckwheat, whole grain etc.

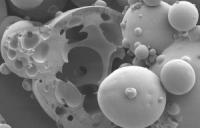

Fillings : chocolate flavors, jellies, fruit pastes, honey, yoghurt, etc.

Shapes : pillows, tubes, bars, triangles, nuts, balls, long and short ovals and specialty profiles, etc.

Production-proven processing techniques and scale-up expertise

Expertly crafted co-extrusion dies with optimized flow design

Product advantages

Product quality and consistency

Pre-engineered dies for producing a wide variety of shapes

Processing capabilities to manage a variety of filling recipes

Possibility to enrich in fibers, vitamins, minerals and other nutrients to create wholesome and healthy foods.

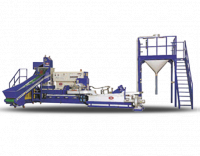

A typical co-extrusion processing line includes mixing and dosing systems, a twin-screw extruder at the heart of the process and shaping equipment. Drying, coating and cooling devices are then used accordingly.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\