Product Specification

| Brand | CHP Industrial Machines |

| Condition | New |

| Warranty | YES |

Product Descriptions

For new filling and packaging lines supplied by OEM’s we developed our “all-in-one” dispensing technology.

The “all-in-one” distribution unit is a modular compact kit designed for each particular conveyor-type providing:

- top lubrication

- bottom lubrication

- inside cleaning

- outside cleaning

The conveyor cleaning is basically an option which is widely appreciated on the market :

- a regular cleaning of product spills remains mandatory to secure the hygiene standard of the filling or packaging line

- some water released in fillers or other distribution equipment do affect some conveyor-strokes with bacterial growth

- manual cleaning interventions result in a considerable manpower cost

- a manual cleaning inside the conveyor mostly requires a dismantling of the belts

- the downtime of a manual cleaning operation reduces the overall line efficiency

These application kits can alternatively be delivered by CHP to the OEM concerned, who pre-assembles these application kits whilst manufacturing the conveyors.

The cleaning agent can be :

- hot water (45°C to 55°C)

- foaming agent (rinsing/foaming/activation/rinsing/drying)

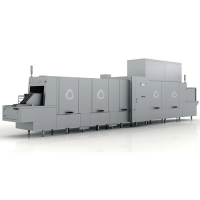

Single strand conveyor equipped with “all-in-one” distribution kit

We supply following units for automatic cleaning of carton package lines :

- mobile cleaning unit CLU-5000-S7-M for hot water or foaming; connected to the line with automatic processing of all cleaning sequences

- Full automatic fixed cleaning unit CLU-5000-AB-F for hot water or foaming

- Full automatic fixed cleaning and MicroDry™ lubrication unit CLU-DLU-5000-S7-F for hot water or foaming

For bottling and canning lines CHP supplies a cleaning installation with booster unit, satellites, PLC, automatic section valves and all piping for a full automatic cleaning of the line.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\