產品規格

| New | |

| YES | |

| Gasoline |

Product Descriptions

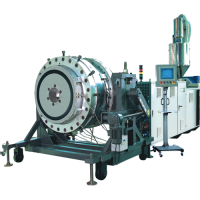

Perfect combination of German quality mindset and Chinese innovation

With the CTE PLUS Coperion Nanjing offers a new twin screw compounding system with a very attractive cost/performance ratio. The CTE PLUS series has been developed with a specific focus on the special needs of small and medium-sized companies in China and Asia in terms of technological requirements and price. As an option the CTE PLUS series can be provided with TÜV CE certification.

The precise manufacturing of the CTE PLUS extruder series ensures the economical processing of a wide range of applications at high product quality. Before delivery each CTE PLUS extrusion system is subjected to a Factory Acceptance Test (FAT) at the Coperion Nanjing site to ensure high quality standards.

KEY BENEFITS OF THE CTE PLUS SERIES

- To improve reliability and to ensure longer life time Coperion Stuttgart, Germany, has engineered new gearboxes for the CTE PLUS that can bear a specific torque of 7.2 Nm/cm³

- New Coperion gearboxes exchangeable with old generation CTE’s gearboxes

- Higher process safety due to new gearbox

- New base frame designed by Coperion, Germany, to ensure higher stiffness

- Gearbox housing manufactured in-house at Coperion Nanjing with CNC machine of Heller, Germany, and checked with 3-dimensional inspection machine of Carl Zeiss, Germany

- Ideal configuration due to modular design

- As flexible as the application - process section according to requirements

- Closely intermeshing, co-rotation twin screws

- Wide range of downstream equipment available

- Final assembly check with 3-dimensional check instrument of Faro, Switzerland

- Before delivery each CTE PLUS extrusion system is subjected to Factory Acceptance Test (FAT) at the Coperion Nanjing site to ensure high quality standards

TYPICAL AREAS OF APPLICATION

- Engineering plastics

- Masterbatch

- Filling

- TPE/TPR/TPV

- Wood composites

- Cable compounds (PVC, HFFR, XLPE, semi-conductive)

- Devolatilization/degassing & reaction

- Direct extrusion

使用 Abraa 安全交易系统进行安全可靠的支付

使用 Abraa 安全交易系统进行安全可靠的支付  \

\