Ürün Özellikleri

| Pearl Electric Co., Ltd. | |

| New | |

| YES |

Product Descriptions

|

Special Features: |

||

| 1. | Low loss,low noise,low partial discharge and high reliability | |

| 2. | Excellent dynamic thermal stability and high anti-lightning impulse capability. | |

| 3. | Epoxy resin pressure casting technology is adopted for HV coils,resulting in much excellent performance. | |

| 4. | Simulation analysis is carried out for core mould designing,to avoid cavity resonance and reduce noise level greatly. Lightning impulse wave simulation calculation and analysis are carried for the HV coils,thus to improve transformer's anti-lightning impulse capability. |

|

Other Advantages: |

|

| 1. | Self-extinguishing and inflaming retarding, fire-proof and explosion-proof, pollution-free and no toxic gas being generated. |

| 2. | Excellent damp-proof performance, capable of working under 100% relative humidity and other harsh conditions, with no damp-removing measures needed. |

| 3. | Thin resin structure realizes chap-free surface and excellent heat-dispersion performance. |

| 4. | Great overload capability, capable of operating continuously under 110% overload conditions and in case of air forced cooling, operating continuously under150% overload conditions. |

| 5. | Nice appearance, small-size, less installation space occupation and low engineering cost. |

| 6. | Each performance index and technical specification excels those specified in China GB, international IEC or industrial standards. |

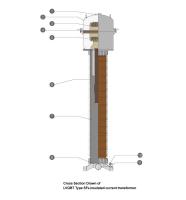

Core:

The core is manufactured with high quality cold rolled grain-oriented silicon steel of high magnetic conductivity. 45° mitring and 5-steps overlapping structure is adopted for the core design, thus to greatly reduce no-load loss and no-load current. To precisely calculate resonance frequency and intensity and avoid cavity resonance generated by the core structure during operation, simulation analysis is carried out for core mould design. Flexible connections are made between core and coils, core and bogie. With these measures adopted, the noise level is reduced by 10~15dB compared with the international standard.

HV winding:

HV winding is manufactured with high quality copper wire, reinforced with glass fiber and being casted with epoxy resin at vacuum state with pressure, having the resin fully impregnated into the coils in the most professional imported equipment. Therefore, product's partial discharge is especially low, for example, transformer of 10kV-level has a partial discharge less than 5 pC. During the HV winding design, rational structure is adopted to improve the electric distribution. With the lighting impulse wave simulation calculation and analysis being carried out with special auxiliary software, product's anti-lightning impulse capacity is greatly improved.

LV winding:

LV winding (with the rated power equal to or higher than 400kVA) is manufactured with high quality foil conductor, resulting in excellent ampere-turn balance, low transverse magnetic flux leakage and higher anti-short circuit capability. By designing reasonable air conduit in the windings to increase the heat-dispersion surface, transformer's temperature rise is effectively controlled and the overload capacity is greatly improved.

Protective enclosure:

Attractive and wearing-resistant protective enclosures are available to provide additional protection to transformer, and the protection level could be IP20, IP23 or higher. The material is stainless steel plate, aluminum alloy plate and other suitable materials. IP20 enclosure provides protection against the entrance of foreign objects with diameter exceeding 12mm and could withstand accidental shock. IP23 enclosure, in addition to functions of IP20 enclosure, also provides protection against rainfall at a vertical angle of less than 60°. But the IP23 enclosure will reduce transformer's cooling capacity by about 5%~10%, therefore this must be taken into account when selecting enclosure for the transformer. Cable support is supplied for HV(LV) incoming (outgoing) connections from bottom of enclosure.

Executed standards:

GB/T10228, GB1094.11, IEC60076-11, DIN42523

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\