Product Specification

| Condition | New |

| Brand | FISCHER |

| Warranty | YES |

Product Descriptions

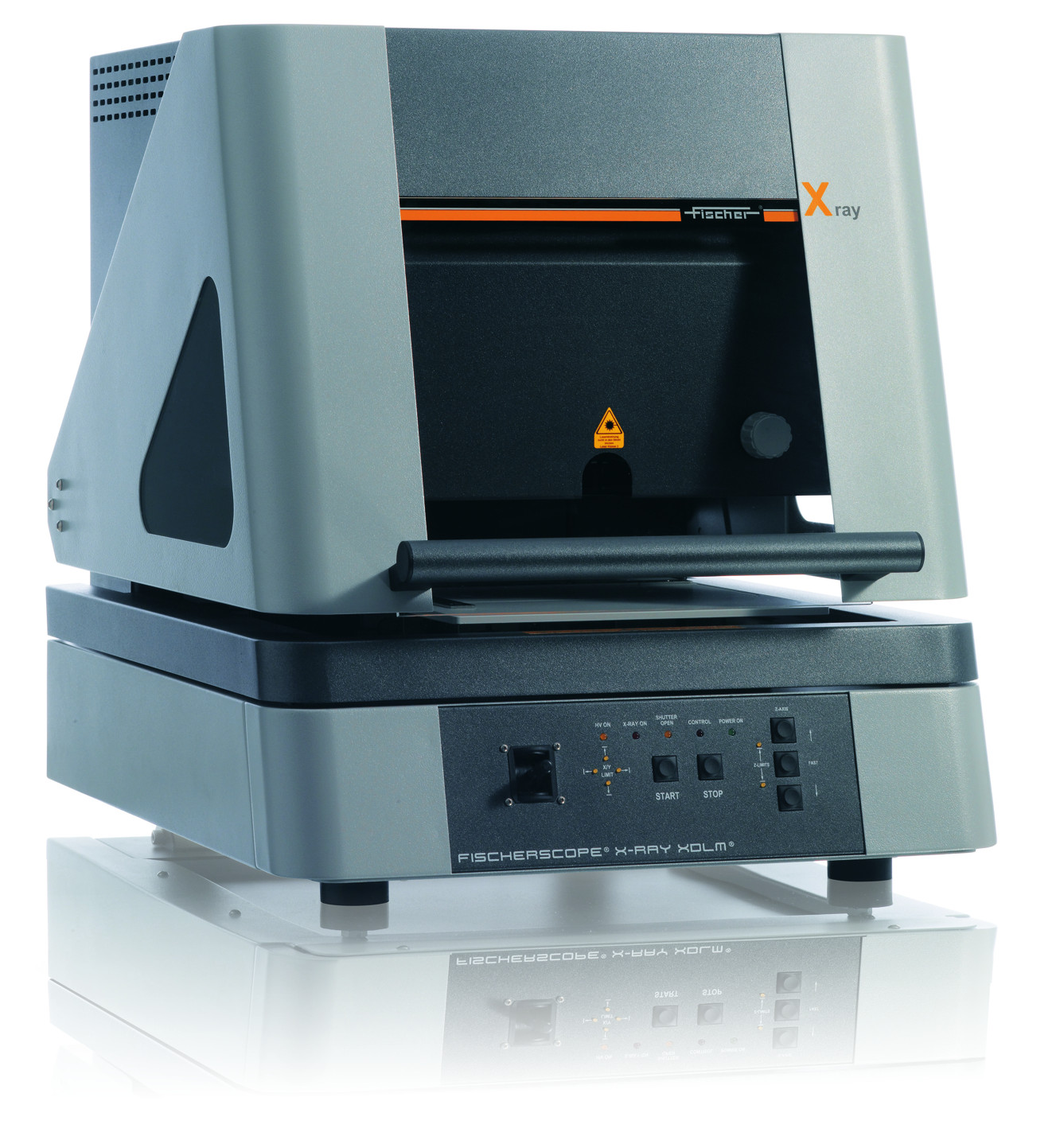

X-Ray Fluorescence Measuring Instruments for the Measurement of Coating Thickness and Material Analysis Coating Thickness

Since 1953, FISCHER has developed and produced innovative measuring technologies for the measurement of coating thickness, materials analysis, micro-hardness measurement and materials testing. Measuring technology from FISCHER is currently employed all around the world – wherever accuracy, precision and reliability are required.

As one of the pioneers in using X-ray fluorescence for industrial measurement, FISCHER quickly recognised the tremendous potential of this method for measuring coating thickness and began developing and manufacturing industrial-strength measuring instruments. The first FISCHERSCOPE X-RAY made its market debut in the early 1980s.

Since then, FISCHER has continued to shape this technology with innovative solutions, which today are stateof-

the-art. One example is the transparent aperture, which allows the user to view the sample from the same direction as the primary beam. Also, the stage that automatically extends upon opening of the hood (the “pop-out function”) was first implemented by FISCHER.

In the software field, FISCHER was the first company to utilise spectra evaluation based entirely on fundamental parameters.FISCHER enforces exacting quality standards in its manufacturing processes and performs meticulous inspection on supplied parts, ensuring the consistently high reliability of FISCHERSCOPE X-RAY instruments.

Today, with over 10,000 units in operation worldwide, the name FISCHERSCOPE X-RAY is synonymous with powerful, reliable and durable X-ray fluorescence measuring instruments. Across the globe, industry, research and science depend on the reliability and accuracy of this equipment. FISCHER consistently rises to the challenge with its dedicated development strategy for producing modern measurement systems and innovative software. Because ultimately, only that which has been designed with the utmost care and built to precise, exacting standards can be expected to perform optimally. And only then does it deserve the name FISCHER. You can rely on that.

The Energy Dispersive X-Ray Fluorescence Analysis (ED-XRFA) is a method for measuring the thickness of coatings and for analysing materials. It can be used for the qualitative and quantitative determination of the elemental composition of a material sample as well as for measuring coatings and coating systems. In both laboratory and industrial environments, this method is now well established and can be readily utilised with modern equipment.

ED-XRFA is a very universal method offering some outstanding advantages. It covers virtually all technically relevant elements and works non-destructively and without contact. Measuring times range in the seconds, rarely longer than one minute. Measurements can be completed quickly and usually without extensive sample preparation. With ED-XRFA, it is possible to measure both thickness and chemical composition of homogeneous materials and coatings. Even traces of harmful substances can be detected in the widest variety of samples.

Moreover, X-ray fluorescence analysis is a very clean method, as no chemicals are used. Due to the protective instrument design, the X-radiation poses no risk for operator or environment: FISCHERSCOPE X-RAY instruments are absolutely safe.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\