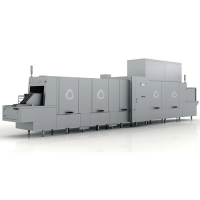

Product Specification

| Condition | New |

| Warranty | YES |

| Fuel Type | Gasoline |

Product Descriptions

This machine is designed to allow the regulation of treatment times from the operator panel through electrically operated solenoid valves on each nozzle, in order to eliminate the limitations typical of normal mechanical rinsers.

In conventional rinsers, in fact, the valves are mechanically operated through cams that are subject to wear, and the only way to vary the injection time of the rinsing fluid is by manually changing the position of these cams.

The electronic rinsers can run single or double treatment cycles (even triple treatment cycles in the special version); the treatment times are established on the basis of the dimensions of the containers, the sterilizing product used and the degree of cleanliness and/or decontamination required.

The advantage of using an electrically operated system, as opposed to a mechanical one, is that of being able to enter a preset injection time for each bottle and of maintaining it constant when the hourly output - and thus the speed of the machine – is varied, with high savings in the consumption of the washing fluids used, as well as elimination of the wear problems typical of mechanical drives. In the case of machines running single treatment cycles, only the spraying time needs to be set, as the rest of the time available is used for the dripping phase.

In the case of the double treatment cycle, on the other hand, it is necessary to set the times of the two separate treatment cycles – to which two separate solenoid valves correspond – and the intermediate dripping time, i.e. that taking place between the injection phases of the two fluids.

The duration of the intermediate dripping time may either be kept constant or varied on the basis of the bottle size, or in proportion to the speed of the machine.

The sequence of the treatment times will, however, always be the same, irrespective of the speed at which the machine is operating.

Promec has developed an innovative (patented) system by means of which, through a proprietary protocol, the individual solenoid valves may be managed simply, practically and safely.

The electronics of the management system are composed of:

A) Central microprocessor for managing in real time all of the valves, i.e. those of the first cycle and those of the second cycle, if any.

B) Local cards for each individual solenoid valve, functioning at 16 bits per valve. The cards are electronically connected in parallel mode and their opening time can vary from 0.1 to 10 seconds.

The cards are operated by a single bipolar lead running from the central collector and connecting the cards in serial mode.

The simplicity of the electrical connections and the flexibility of the system are the main features of the new electrically operated system, patented by Promec.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\