Product Specification

| Condition | New |

| Warranty | YES |

Product Descriptions

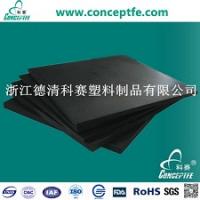

INTRODUCTION:

Expanded PTFE sheet (Soft Fibration PTFE sheet) is made of 100% PTFE through a special process. It is made up of countless homogeneous, fine, soft, multidirectional fibers. It has high tensile strength, low creep, high and low temperature resistance, corrosion resistance, no asbestos, no additives, non-toxic, aging resistance. It also comply with FDA requirements. After compression, its fiber tangles mutually, and becomes more closer, airtight, watertight and better performance of anti leakage. Under severe corrosive environment and high temperature, it can still maintain excellent sealing.

APPLICATIONS:

It is used as sealing material for various kinds of flanges. It can be used in chemical industry, food industry, pharmacy industry, semiconductor industry, aerospace industry, petrochemical industry, paper industry, ship-building industry and medical equipment.

TECHNICAL PROPERTIES

Temperature range: -260℃--+260℃

Operating pressure: vacuum to 207kg/cm2(3000psi)

Chemical resistance: (PH 0-14) except motten alkali metals and elemental fluorine.

Stability: no subject to aging, store indefinitely, and free from contamination.

Low creep: easy to install and fasten. After construction, it is not easy to be deformed.

Safety: complies with FDA21 CFR177.1550

It is the ideal products for food and pharmaceutical industries.

Its superior compliance depends that it can be used for crude or damaged flanges.

SPECIFICATIONS FOR SHEET

|

0.5MM*1520MM*1520MM |

3.0MM*1520MM*1520MM |

|

1.0MM*1520MM*1520MM |

4.0MM*1520MM*1520MM |

|

1.5MM*1520MM*1520MM |

5.0MM*1520MM*1520MM |

|

2.0MM*1520MM*1520MM |

6.0MM*1500MM*1500MM |

|

2.5MM*1520MM*1520MM |

7.0MM*1500MM*1500MM |

|

THICKNESS |

SEALABILITY (ml/hr) |

COMPRESSION RATIO (%) |

ELASTIC RESILIENCE RATIO (%) |

STRESS RELAXATION RATIO(%) |

|

0.8MM |

0.06 |

63.6 |

8.8 |

16.3 |

|

2.0MM |

0.17 |

63.4 |

9.1 |

37.1 |

|

STANDARD |

ASTM F37B |

ASTM F36 |

ASTM F36 |

ASTM F38 |

NOTE: TESTING RESULT (TAKE 0.8MM AND 2MM SHEET FOR EXAMPLE ACCORDING TO ASTM)

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\