Ürün Özellikleri

| Clextral Machinery | |

| New | |

| YES | |

| Others | |

| Gasoline |

Product Descriptions

A great classic with a modern twist

Flakes, crusty toasted petals, are the great classical breakfast food and have been adopted by a majority of consumers around the world. The twin-screw extrusion lines allow to process a vast range of recipes adapted to all tastes and needs.

Flakes are either consumed plain or coated with a variety of sugars, malted ingredients, honey, fruit flavours, chocolate, etc. “Corn flakes” are the most famous variety but many other cereals can be used such as wheat, rice, oats, barley, rye, buckwheat…. A new variety of “multigrain” or “multicereals” flakes made with a mix of visible cereals inclusions became very popular. To meet the increasing demand for healthy cereals, whole grain or grains enriched with fibers, vitamins, minerals and other nutrients are also used.

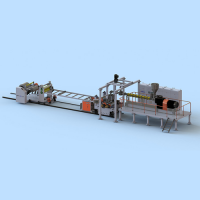

Clextral twin screw flakes extrusion : more flexible and more cost-effective

Over the years, many food manufacturers have adopted Clextral twin-screw extrusion systems to produce flakes because this technology offers many advantages compared to conventional batch cooking process :

Quick processing time : 15 to 20 minutes vs 8 to10 hours for the batch process

Flexibility to create a wider range of products

Raw material versatility : corn, wheat, bran, oat flakes

Wide range of products opportunities : flakes, direct expanded, co extruded.

Reduced operating costs :

Much lower investment cost

Quick process

Quick start-up, shut down and product changeover

Energy & water savings : only 23% RH out of the extruder, water consumption reduced by 1,5 compared to batch cooking

Reduced raw material costs

Continuous fully automated processing lines to produce consistent quality product while maintaining organoleptic characteristics close to the flakes manufactured with conventional batch cooking.

Compact design with reduced floor space

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\