Ürün Özellikleri

| New | |

| YES | |

| Gasoline |

Product Descriptions

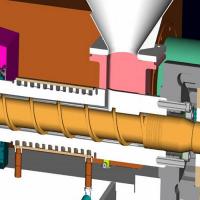

From polymer resins, the materials are being melted in the extrusion die to produce high quality films for various type of application. The end-products are the following:

1. CPP Films (cast propylene) – good transparency, scratch resistance, moisture and water proof, heat resistance but inferior in gas barrier property. CPP is a good replacement for LDPE/LLDPE because of its glossy appearance and low haze properties but it has higher sealing temperature than polyethylene materials. The following are the kinds of CPP film being produced in our east line: |

A. CPP Laminating grade

(2-sides heat sealable/1-side corona treated; from 20micron to 200micron thickness)

– transparent, white or any color variants, CPP lamination films are commonly used as replacement for BOPP and LDPE film materials. Used as lamination substrates for noodles, biscuit, soap/detergent and other laminated packaging materials.

B. CPP print/bag grade

(2-sides heat sealable/1-side corona treated; from 20microns to 200micron thickness)

– transparent, white or any color variants, it is used for single-film packing for sugar, bakery bags, soap/detergent wrappers and other packing materials.

C. CPP metallizable grade/CPP metallized film

(2-sides heat seallable/1-side corona treated; from 20micron to 80micron thickness)

– metallized film is a replacement for aluminum foil film. Although metallized film is inferior in quality ang properties compared to aluminum foil as barrier film for laminated products, it has almost the same characteristics of foil and cheaper in price. Used as lamination substrates for chips snack, confectionary products and other packaging materials.

2. Stretch Films (20micron to 35micron thickness) |

3. PA/PE (50microns to 250microns thickness)

|

|

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\