Ürün Özellikleri

| Clextral Machinery | |

| New | |

| YES | |

| Others | |

| Gasoline |

Product Descriptions

Leveraging its EPT™ (Extrusion Porosification Technology), Clextral proposes original solutions to manufacture porous powders with enhanced functionalities, using less energy. EPT™ can advantageously replace conventional techniques, such as drying by atomization and lyophilizing. This technology can be used for numerous food processing applications and for the manufacturing of innovative chemical and pharmaceutical products.

How was EPT™ developed and what advantages does it offer?

EPT

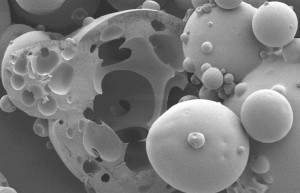

EPT™ is a Clextral patented process, developed in collaboration with New Zealand and Australian partners. Using continuous twin-screw technology, EPT™ is useful in texturing powders to provide them with new functions. The twin-screw extruder is configured to continuously process highly viscous and heat-sensitive products, using mechanical action adapted to the function (mixing, limited shearing, controlled residency time) and precise temperature control. EPT™increases drying efficiency by accelerating material and heat transfers. This enables the manufacturing of complex powders with homogenous features and interesting rehydration properties, at a lower cost, in particular through lower energy consumption during the concentration and drying phases.

Who can benefit from EPT™?

The EPT™ process is a flexible, economical and compact alternative to conventional technologies. This intensified drying-texturing process was first tested for the manufacturing of milk powders and their derivatives. The process was then extended to other added value food products: protein-rich powders, high-fat mixes, heat-sensitive ingredients (aromas, bacteria), instant drinks, etc. Clextral and its partners are currently exploring EPT™ applications in non-food areas, including fine chemicals and pharmaceuticals.

To allow its customers to assess the potential of this process, Clextral has designed and markets a pilot line with evaporative capacity of 30 to 50kg/h of water. Clextral also proposes a full range of support services to help develop innovations.

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\