產品規格

| Farhat Bakery Equipment | |

| New | |

| YES | |

| Others |

Product Descriptions

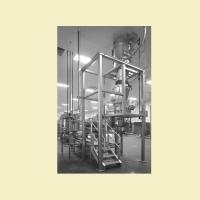

Heavy duty divider, with output of 1, 2, 3, 4, 5, 6 or 8 rows, suitable for dividing soft and semi-hard bulk dough into equal pieces at equal intervals using an electro-pneumatic device and a wide range of dough weight by using an appropriate built-in device which allows easily selects the required weights of dough pieces.

The machine is equipped with conical shape dough tank hopper equipped with special system to prevent dough from forming air bubbles.

The transfer of bulk dough into balls is accomplished by means of Stainless Steel helicoidal shaft. The dough balls are delivered to intermediate proofer on a cotton food grade non-stick belt. This belt is equipped with flour duster and a pressing device which can be used in case of soft dough.

Production is electronically variable from 600 to 3000 pcs/hour per row, with a weight range from 40 to 250 grams. The Betta is also available with touch-screen control panel, with many storable programs, that controls and stores all the machine functions, from adjustment of sizes to production speed, with diagnostics for possible operational problems

使用 Abraa 安全交易系统进行安全可靠的支付

使用 Abraa 安全交易系统进行安全可靠的支付  \

\