Product Specification

| Brand | Winan |

| Condition | New |

| Warranty | YES |

Product Descriptions

PRINCIPLE OF OPERATION

The instructions for filling are provided with the equipment. Once the main water flow is established and water inlet and foam outlet valves are opened, the water enters the area between vessel wall and bladder, applying pressure to the bladder. The foam concentrate is forced out of the bladder through the foam concentrate outlet pipe and into the ratio controller through metering orifice. The concentrate pressure and water inlet pressure at ratio controller will be same, as the main water supply pressure is utilised to expel the foam from the bladder.

The water flowing through the ratio controller jet creates a low pressure area common both to down stream water and foam concentrate. This injects the concentrate in to the ratio controller through an accurate sized orifice proportioned to water venturi. This ensures correct proportioning over a wide range of flow condition.

The bladder tank proportioning system operates on same principle as that of a balance pressure proportioning system. In bladder system, the bladder is used as diaphragm to separate the water and foam concentrate within the tank. The foam concentrate is injected into the ratio controller utilising water pressure.

The system is also supplied with foam concentrate control valve as an optional item. The valve allows concentrate flow only when minimum of 2.1 kg/ sq.cm. water pressure is established in the system. For pressure drop and flow characteristics refer catalogue of ratio controller.

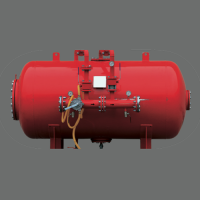

SELECTION OF HORIZONTAL /VERTICAL BLADDER TANKS

Advantages of Horizontal bladder tanks

(i) Better stability than vertical tank in earthquake prone area

(ii) Easier to refill than vertical tanks

(iii) Easy to transport, store and install

(iv) Large Capacity

Advantages of Vertical bladder tanks

(i) Require less floor space than horizontal tanks

INSTALLATION, INSPECTION AND MAINTENANCE

An installation, inspection and maintenance manual is packed with each unit. The manual provides detail schematic, initial procedure, inspection and maintenance procedures. The instruction manual must be read carefully and during installation and commissioning of the system.

After few initial successful tests an authorised person must be trained to perform inspection and testing of the system. It is recommended to carry out physical inspection of the system regularly, the inspection should verify that no damages have taken place to any component and all the valves are in their proper position as per the system requirement. The system should be fully tested at least once in a year and in accordance with applicable NFPA code or in accordance to the guidelines of the organisation having local jurisdiction.

Do not turn off the system or any valve to repair or test the system, without placing a roving Fire Patrol in the area covered by the system. The patrol should continue until the system is put back in service. Also inform the local security personnel and the control room so that a false alarm is not signalled.

CAUTION

1) Do not weld on the tank as it may damage the bladder fitted inside the tank.

2) Release pressure before an inspection and maintenance of the system.

3) Sight gauge is not pressure tight, so before taking concentrate level reading, tank pressure must be released.

4) The bladder tank is to be installed under a shade to avoid direct sunlight on the equipment.

5) While designing a foam system, step shall be taken to allow for removal of the internal centre tube(s). The centre tubes are full length and/or height of the bladder tank.

6) ASME Code may require over pressure protection before pressurising the system. WINAN FIRE does not supply an over pressure relief valve with the tanks. It shall be the owner’s responsibility to provide over pressure protection for the tank in accordance to ASME Code.

7) Foam concentrate filling procedure must be . Incorrect filling procedure may damage the bladder. WINAN product have limited warranty and incorrect fill procedure will void the warranty.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\