Product Specification

| Feininger | |

| New | |

| YES | |

| 380 | |

| 250 | |

| 30000 | |

| CE | |

| Plastic Sheet |

Product Descriptions

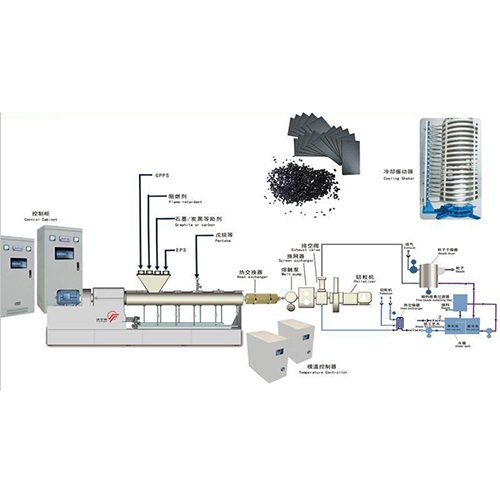

Feininger newly developed graphite EPS extrusion equipment production line adopts scientific extruder design. With rich production experience and advanced parallel twin screw design concept, through an uniform temperature of the heat exchanger, the discharge holes are not blocked, so that the finished product with perfect quality.

By extrusion molding thermoplastic foam particles in water, which requires very high water pressure. Water temperature and water pressure with the scientific design of the discharge holes are not blocked, but also to avoid foaming early in the pipeline, after centrifugal drying, cooling needs by vibrating the beads using bottom-vibration design to ensure more efficient production and high-quality products .

Currently, Feininger has a wealth of experience in the production of graphite EPS and free technical training for customers, Feininger graphite EPS production line will give customers maximize the effective and stable operation of equipment and efficiency, without having to spend a lot of time and costs in commissioning and run on.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\