Product Specification

| Brand | Clextral Machinery |

| Condition | New |

| Warranty | YES |

| Mechanical Condition | Others |

| Fuel Type | Gasoline |

Product Descriptions

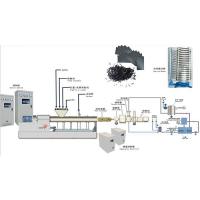

Clextral’s Green Extrusion technologies include a full range of purpose-built systems to enable more efficient and cleaner industrial processing of pulp and paper, plastics, chemicals and energy products. Specializing in bio-sourced materials, Green Extrusion technologies also contribute to environment friendly production because they enable intensified processes based on the principle of “making more with less”, in terms of the use of raw materials, energy, water and reagents.

How does Green Extrusion work?

green extrusion

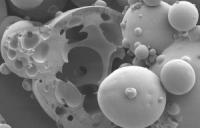

Extrusion processing is a continuous method that physically and/or chemically converts viscous media with a high level of consistency, flexibility and productivity. Through the use of dedicated screw configurations, as well as accurate control of time-temperature parameters in screw extruders, the raw materials are subjected to a series of process functions such as conveying, compressing, heating, melting, mixing, shearing, cooling, venting, pumping and shaping. The sequence and intensity of the process functions are adjusted appropriately according to manufacturing requirements and products specifications.

Co-rotating twin screw extruders are particularly well adapted to ensure consistent processing. This is achieved by the action of two identical intermeshing screws, mounted on splined shafts, and surrounded by an eight-shaped modular barrel. The screw profile can be modified to a wide range of screw designs, thus enabling various configurations of the screw-barrel assembly.

Green Extrusion technologies leverage the basic process functions of intermeshing, co-rotating twin screw extruders to process various raw materials, often bio-sourced, essentially using extruder technology to achieve intensified and continuous chemical reactions.

Applications of Green Extrusion Technologydev_durable_anglais_CMYK

Cellulose pulping

Synthesis of chemical products and polymer materials (reactive extrusion)

Production of energetic materials

Biodegradable compounds,

Recycled plastics

Bio-sourced plastics

Biomass pre-treatment

Green Extrusion Technology contribute to Sustainable Development

Value creation through the optimization of bio-sourced and recyclable resources

Intensification of processes, generating water and energy savings and minimizing operating costs

Improvement of operator’s working conditions, with up-to-date facilities and processes that comply with the latest health and safety standards

Diversified business models, enabling end users to innovate and produce a wide range of environmentally friendly products

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\