Product Specification

| Brand | Solico Tanks |

| Type | Other Plastic Building Materials |

Product Descriptions

Founded in 1966 and headquartered in the UAE, Solico Tanks is a global leader in water storage solutions. Specializing in GRP water tanks, the company combines decades of expertise with cutting-edge manufacturing to deliver tanks that are durable, eco-friendly, and tailored to diverse needs. With a strong commitment to sustainability and innovation, Solico Tanks continues to set industry benchmarks, offering trusted solutions for residential, industrial, and municipal water storage worldwide.

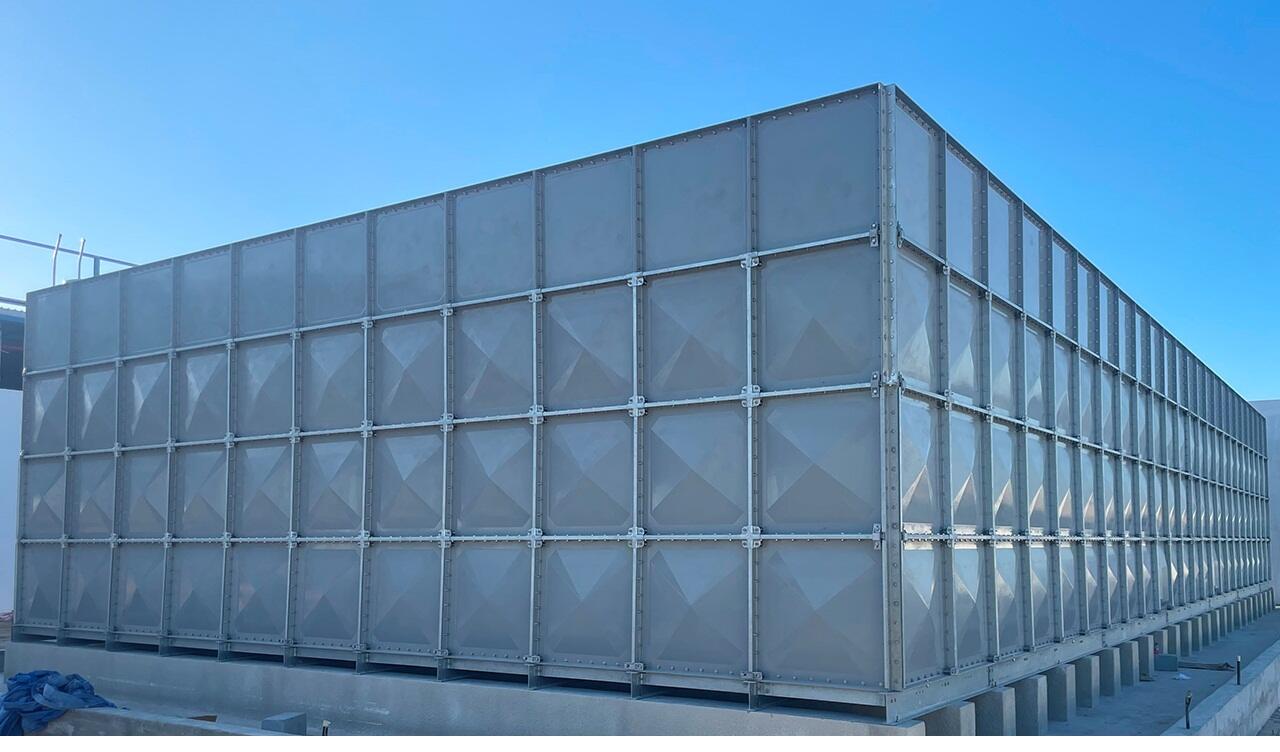

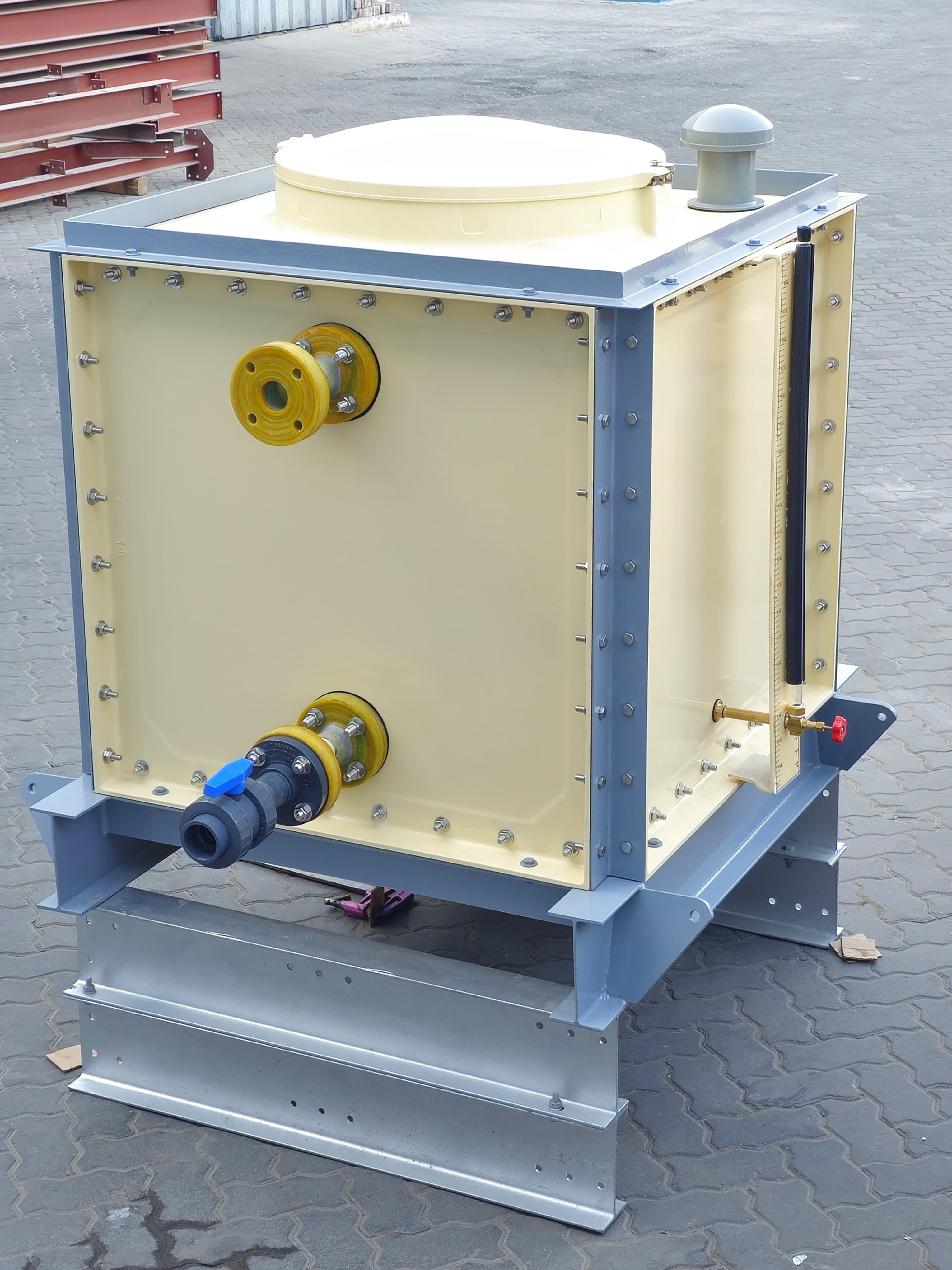

Glass Reinforced Plastic (GRP) water tanks are a modern solution to water storage needs, offering unparalleled durability, corrosion resistance, and adaptability. These tanks are designed to meet the demands of diverse environments, from residential homes to industrial facilities and municipal projects. At Solico Tanks, GRP water tanks are crafted with precision and advanced technology, ensuring long-lasting performance and reliability.

The modular design of GRP tanks enables easy transportation and installation, even in challenging or remote locations. This versatility makes them a preferred choice for large-scale water storage projects and customized applications.

Solico Tanks employs state-of-the-art SMC (Sheet Molding Compound) hot press technology to manufacture its GRP water tanks. This advanced process involves compressing fiberglass-reinforced materials and isophthalic-based resin under high temperatures and pressure. The result is a dense, uniform panel with exceptional strength and resistance to UV rays, chemicals, and extreme weather.

- Material Preparation: High-quality fiberglass and resin compounds are prepared and inspected for consistency and quality.

- SMC Sheet Formation: The materials are layered to form SMC sheets, ensuring optimal strength and uniformity.

- Hot Pressing: Using automated hot press machines, the sheets are molded into panels under precise temperature and pressure conditions. This step enhances durability and ensures uniform panel thickness.

- Assembly and Quality Control: Panels are assembled into modular tanks of various sizes, ranging from 1,000 liters to 15,000,000 liters. Each tank undergoes rigorous quality checks to meet international standards, such as ISO 9001, NSF 61, and WRAS certifications.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\