Product Specification

| Zhejiang Shuanglin Machinery Co., Ltd | |

| New | |

| YES |

Product Descriptions

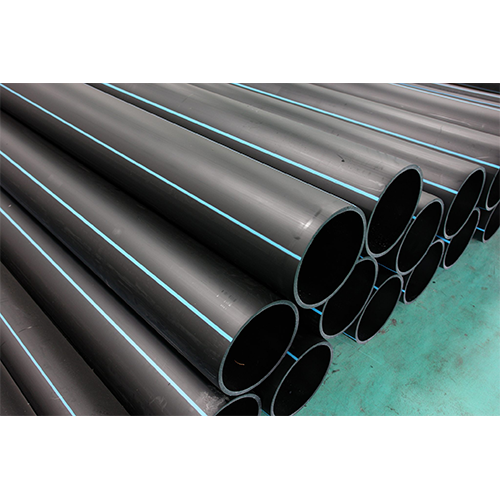

HDPE Pipe

HDPE Is A High Crystallinity, Non-Polar Thermoplastic Resin. HDPE Appearance Of The Original State Was Milky White, In The Meager Section Of A Certain Degree Of Translucent. PE Has Excellent Resistance To Most Of The Characteristics Of Life And Industrial Chemicals. Certain Types Of Chemicals Can Cause Chemical Attack, Such As Corrosive Oxidants (Concentrated Nitric Acid), Aromatic Hydrocarbons (Xylene) And Halogenated Hydrocarbons (Carbon Tetrachloride). The Polymer Does Not Absorb Moisture And Has Good Water Vapor Resistance, Can Be Used For Packaging Purposes. HDPE Has Good Electrical Properties, Especially Dielectric High Dielectric Strength, Making It Very Suitable For Wire And Cable. Medium To High Molecular Weight Grades Have Excellent Impact Resistance, Even At Room Temperature And At -40F Low Temperature Are So.

HDPE Pipe

PE Can Be Manufactured In A Wide Range Of Different Processing Methods. Including Such As Sheet Extrusion, Film Extrusion, Tube Or Profile Extrusion, Blow Molding, Injection Molding And Rotational Molding.Extrusion: The Grades Used For Extrusion Production Generally Have A Melt Index Of Less Than 1 And Medium To Wide MWD. During Processing, A Low Melt Flow Rate Of MI Can Be Obtained. Wider MWD Grades Are More Suitable For Extrusion Because They Have Higher Production Speeds, Lower Die Pressures And Less Tendency To Fracture Of The Melt.

Use

PE Has Many Uses, Such As Wires, Cables, Hoses, Pipes And Profiles. Pipe Applications Range From Small-Bore Yellow Tubes For Natural Gas To Thick-Walled Black Tubes For Industrial And Urban Pipelines Up To 48 In Diameter. Large-Diameter Hollow-Wall Tubes Are Rapidly Growing As Alternatives To Rainwater Drains And Other Sewer Pipelines Made Of Concrete.

Sheet And Thermoforming

Many Large-Scale Picnic Refrigerators Thermoformed Lining Is Made Of PE, With Toughness, Light Weight And Durability. Other Sheet And Thermoformed Products Include Fenders, Tank Liners, Pan Pots, Transport Cases And Cans. A Large Number Of Rapidly Growing Sheet Applications Are Mulch Or Pond Village, Which Is Based On MDPE With Toughness, Chemical Resistance And Impermeability.

Blow Molding

HDPE1 / 3 Sold In The United States For Blow Molding Purposes. These Range From Bottles With Bleach, Oil, Detergents, Milk And Distilled Water To Large Refrigerators, Car Fuel Tanks And Cans. Blow-Grade Properties Such As Melt Strength, ES-CR And Toughness Are Similar To Those Used For Sheet And Thermoforming Applications, So Similar Grades Can Be Used.

Injection

Blow Molding Is Often Used To Make Smaller Containers (Less Than 16 Oz) For Packaging Pharmaceuticals, Shampoos And Cosmetics. One Advantage Of This Process Is That The Production Of The Bottles Automatically Goes To The Corners Without The Need For Post-Finishing Steps Such As General Blow Molding. Although Some Narrow MWD Grades Are Used To Improve Surface Finish, Medium To Wide MWD Grades Are Generally Used.

Injection Molding

There Are Countless Applications For HDPE Tubing, Ranging From Reusable Thin-Walled Beverage Cups To 5-Gsl Cans, Which Consume 1/5 Of The Domestic HDPE Production. Injection Grade General Melt Index Of 5 To 10, There Is A Lower Mobility And Toughness Of The Mobility Of Grades With Higher Mobility. Applications Include Thin-Walled Packaging For Daily Necessities And Food; Tough, Durable Food And Paint Cans; And High Resistance To Environmental Stress Cracking Applications Such As Small Engine Fuel Tanks And 90-Gal Cans.

Rotational Molding

The Material To Be Processed In This Manner Is Generally Pulverized Into A Powder Material Which Is Melted And Flowed During The Thermal Cycle. Rotomoulding Uses Two Types Of PEs: Universal And Cross-Linkable. The General-Purpose MDPE / HDPE Typically Has A Density Range From 0.935 To 0.945 G / Cc With A Narrow MWD Giving The Product High Impact And Minimal Warpage With A Melt Index Range Of 3-8. Higher MI Grades Are Generally Unsuitable Because They Do Not Possess The Desired Impact And Resistance To Environmental Stress Cracking Of Rotomoulded Articles.High Performance Rotomolding Applications Utilize The Unique Properties Of Their Chemically Crosslinkable Grades. These Grades Have Good Flowability During The First Period Of The Molding Cycle And Are Then Crosslinked To Form Their Excellent Resistance To Environmental Stress Cracking And Toughness. Abrasion Resistance And Weather Resistance. The Cross-Linkable PE Is Only Suitable For Large Containers, Ranging From 500-Gal Transport Of Various Chemical Tanks To 20,000-Gal Agricultural Tanks.

Film

PE Film Processing Is Generally Used Ordinary Blown Film Processing Or Flattening Processing Method. Most PEs Are Used For Thin Films, And General Low Density PE (LDPE) Or Linear Low Density PE (LLDPE) Are Available. HDPE Film Grades Are Generally Used Where Tensile Strength And Impermeability Are Required. For Example, HDPE Films Are Commonly Used In Commercial Bags, Grocery Bags And Food Packaging.

Product Performance

High Density Polyethylene Is Non-Toxic, Odorless, Odorless White Particles, The Melting Point Of About 130 ℃, The Relative Density Of 0.941 ~ 0.960. It Has Good Heat Resistance And Cold Resistance, Chemical Stability, But Also Has A High Rigidity And Toughness, Good Mechanical Strength. Dielectric Properties, Resistance To Environmental Stress Cracking Is Also Better.

Matters Needing Attention

1, Outdoor Open Laying, Where There Is Sunlight, It Is Recommended To Do Shelter Measures.

2, Buried HDPE Pipe, DN ≤ 110 Of The Pipeline Can Be Installed A Little Snake Summer Laying, DN ≥ 110 Of The Pipeline Due To Sufficient Soil Resistance, Can Withstand Thermal Stress, No Need To Set The Tube Length; Reserved Pipe Length.

3, HDPE Pipe Installation, If The Operating Space Is Too Small (Such As: Pipe Wells, Ceiling Construction, Etc.), Should Be Fused Connection.

4, Hot Melt Socket Connection, The Heating Temperature Can Not Be Too High, Too Long, The Temperature Is Best Controlled At 210 ± 10 ℃, Or Will Cause Excessive Melt Within The Extrusion Parts, Reducing The Water Diameter; Or Pipe Interface Should Be Clean, Or Will Cause The Socket To Disconnect The Water Leakage; The Same Time, Pay Attention To Control The Angle And Direction Of The Pipe, To Avoid Rework.

5, Hot Butt Connection, The Required Voltage Between 200 ~ 220V, If The Voltage Is Too High, Will Cause The Heating Plate Temperature Is Too High, The Voltage Is Too Low, Then The Docking Machine Can Not Work Properly; Docking Should Be Aligned On The Interface, Otherwise Will Cause Insufficient Docking Area Requirements, Weld Strength Is Not Enough, And Curling Not Into; Heating Plate When The Pipe Interface Is Not Disposed Of Clean, Or Hot Plate With Oil, Sediment And Other Impurities, Will Cause The Interface To Disconnect The Water Leakage; Heating Time To Control, And Heating Time Is Short, Tube Heat-Absorbing Time Is Not Enough, Will Cause The Weld Seam Is Too Small, The Heating Time Is Too Long, Will Cause The Weld Seam Is Too Large, It Is Possible To Form Weld.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\