Ürün Özellikleri

| Husky | |

| New | |

| YES | |

| Excellent (No problems or history of failures) | |

| Gasoline |

Product Descriptions

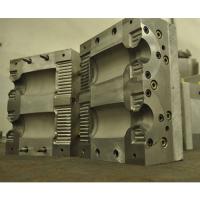

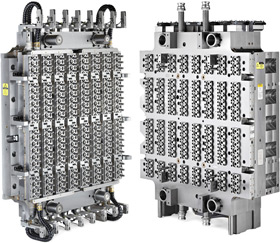

Preform tooling and servicesAs the world’s largest mold maker, Husky is able to deliver global tooling programs for new preform molds or conversions of existing tooling to latest generation technology or cavitation. Preform molds are produced at dedicated state-of-the-art facilities and we are continually investing to increase capacity, reduce lead times and maximize part quality.Husky preform molds feature:Industry-leading productivity based on fast cycle times and high efficiency levelsHigh quality materials and proven mold designs to ensure long mold lifeUltra hot runners feature a spring pack that increases the temperature operating range and eliminates leaking plasticMold ID sets operating parameters for each tool and allows for porting of that optimized process from machine to machine – eliminating potential human error for correct start-up and operating proceduresLowest cavity-to-cavity weight and dimensional variability as a result of best-in-class manufacturing machines and processes

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\