Product Specification

| Brand | COPAR |

| Condition | New |

| Warranty | YES |

Product Descriptions

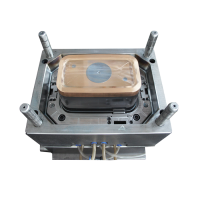

Stretch blow molding is best known for producing PET bottles commonly used for water, juice and a variety of other products. Stretch blow molding has been used for packaging detergent, and has grown in existence with the primary use for making carbonated beverage bottles.

One of the major advantages of stretch blow molding is the ability to stretch the preform in both the hoop direction and the axial direction. This biaxial stretching of material increases the tensile strength, barrier properties, drop impact, clarity, and top load in the container. With these increases it is usually possible to reduce the overall weight in a container by 10 to 15 percent less than when producing a container in another way.

Generally injection blow molded container's material is distributed evenly throughout and do not need any trimming or reaming.

Stretch blow molding is divided into two different categories single-stage and two-stage. Where our long experience permits for us the design and the realization of molds for the following:

• Single stage: (one Machine)

1. Injection Mold

2. Heating Mold

3. Blowing Mold

• Two Stages

1. PET Perform Mold

2. PET Blowing Mold

We are supported by the most innovated technology for perform simulation, where we can simulate and optimize the preform design for the best economic solution.

The Hot Runner system for these special Molds are from the world leaders such as Mold Master, Automa and many others.

Material is a combination of aluminum and stainless steel or beryllium cupper, cavities brilliant polished.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\