Product Specification

| Condition | New |

| Brand | KULP MACHINERY |

| Packaging Type | Bottles ,Others |

| Application | Beverage,Chemical ,Food,Machinery & Hardware,Medical |

| Packing Speed (P/Min) | Up to 6000 package per hour |

| Operational Mode | Automatic |

Product Descriptions

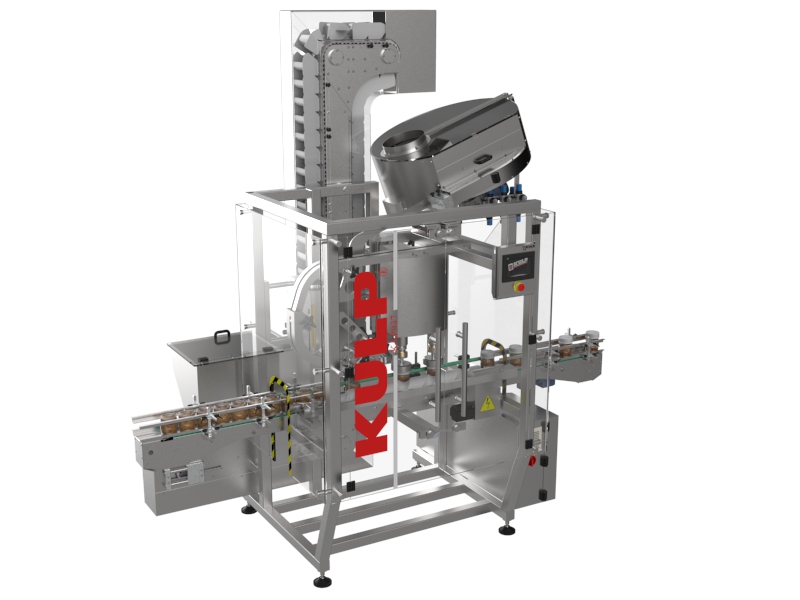

Our capping machines are designed to close plastic screw caps or metal twist off caps, bucket lits or press caps. The capping units work with the pneumatic system and takes its motion from an air motor. They havet has a special plastic end, which is designed according to customer’s caps. This plastic unit prevents damage of the caps because of friction. During the operation caps are placed on the recipient either manually or automatically through an elevator. Then the recipients are stopped under the capping system on the conveyor automatically. The capping unit dives to the recipient and closes the caps. Finally, recipients are released by the system on the conveyor, which speed is adjustable. On average, the capping system has 2 meters conveyor, which has a speed control on the control panel. It’s easy to change from one package diameter to another, and height adjustment is done by the hand wheel and the numerator, the side rails and the indexing system are also adjustable according to the width diameter or width of the packages. There are sensors to automatically detect when there is package on the conveyor line. Our machines are in a simple and robust design, with a heavy duty stainless steel frame, and a plastic mould to prevent the caps from being damaged because of friction.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\