Product Specification

| BioMashin | |

| New | |

| YES | |

| Others |

Product Descriptions

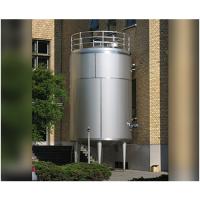

In the production lines for milk processing, the Silo tank serves to take and store at atmospheric pressure a given volume of raw, pasteurized, skim milk, or whey.

During the storage process, milk is very delicate; therefore, the mixing process should be very careful so that fat molecules release is prevented. More than that, increase in storage temperature with 15 degrees Celsius results in increase of 250 times in the number of bad bacteria per milliliter milk. This is why temperature control during storage and processing is a crucial factor. The equipment that Biomashin offers aims to control these processes effectively and in the most optimal way.

Our storage tanks ensure maximum product protection during its storage.

Biomashin offers Silo tanks with standard dimensions and equipment. However, they could be customized upon request – designed in accordance with a particular technical specification. Silo tanks could be produced on legs or support ring.

Silo tank for raw/pasteurized milk storage basic design

- Volume: up to 250m3 built in the workshop

- Made of stainless steel AISI 304

- Surface in contact with the product 2В, welding seams polished with sandpaper Р180, Ra≤ 1.2µm

- Insulation made of mineral wool – on shell and top. Insulation cladding is made of stainless steel and is fully welded. Accurate calculation of exact insulation thickness for Silos stored outside depends on the specific climate conditions.

- Agitator with precisely calculated speed and construction, without foaming and stratification of milk, and with uniform action in the entire volume

- Cleaning system with specially selected elements and calculated parameters ensuring impeccable cleaning

- In high temperature environment and depending on the period for milk storage, Silo tanks could be produced with cooling jackets to maintain milk temperature

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\