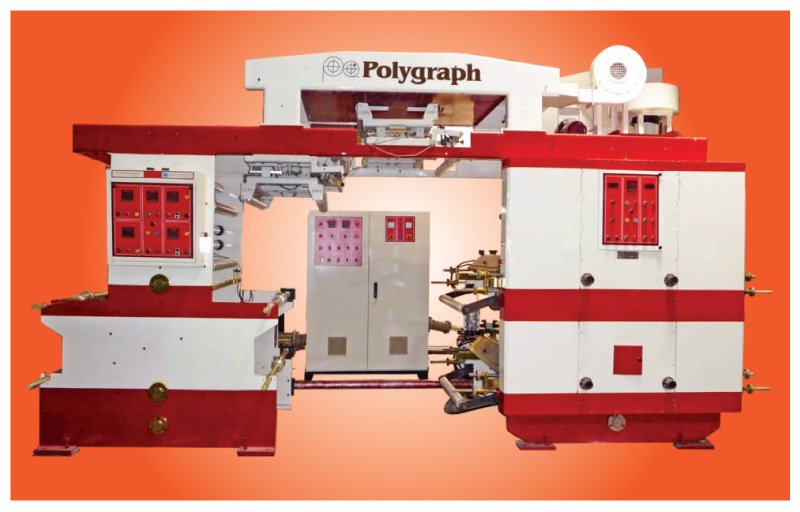

Product Specification

| Brand | POLYGRAPH PRINTING TECHNOLOGIES LTD. |

| Material | Aluminum |

Product Descriptions

A Technological Marvel. "A substitute” to the Central Impression Flexo Printing Press. A Flexible Flexographic Solution To the World.

Print more. Print your Imagination.

6 FACTS

· Motorised Length & Side Register Control System

· Sleeves System for Plate Mounting

· Hydraulic lift on/off Plate cylinders and continuous rotation of inking rollers

· 5 Motor Drive Automatic Tension Control System

· Chambered Doctor Blade System

· Ceramic Anilox Rolls

Technical Specification:

- Sleeves System

- for Plate Mounting instead of Plate Cylinders, for easy and fast changeovers of jobs

- Opto Electronic Web Guiding System

- digitally controlled web guiding for precise guiding of web

- Automatic Tension Control System

Load Cell feed back control provided on Unwind, Infeed, Outfeed & Rewind Station to maintain uniform tension throughout the entire roll.

|

5 Motor Drive (5MD) technology for: |

|

1. Unwind Station |

|

2. In feed Station |

|

3. Main Printing Station |

|

4. Out Feed Station |

|

5. Rewind Station |

|

|

Hydraulic System

Provided for continuous rotation of Inking Rollers and Auto Lifting of Plate Cylinders when machine is printing in OFF mode. This prevents drying of inks on the Anilox Roller.

Chamber Doctor Blade System

For uniform & controlled ink supply on the Anilox Roll.

Ceramic Anilox Rolls

Higher mesh laser engraved Anilox rollers for precise transfer of ink to achieve better and enhanced print quality.

Double Diaphragm Ink Pumps

Air operated pumps for controlled circulation of ink between Ink Tank & Chambered Doctor Blade.

Web Video System

Web Inspection System, equipped with high quality color camera, Quick Zoom & Split Screen, mounted on motorised

traverse bar to monitor complete print at all speeds.

Pneumatic Shaft

Provided on Unwind and Rewind Station for quick and easy loading and unloading of the Parent roll.

Pneumatically operated Nip Rollers

to maintain uniform & precise tension at printing, infeed and outfeed stations.

OUR FEATURE PRODUCTS ARE:

·Flexo Printing Press(2 to 12 colors) for

. LD,LLDPE, PP, HMHDPE, BOPP & PET

. Zip Lock Bags

. Woven Fabric (Roll to Roll)

· Rotogravure Printing Press (2 to 10 colors)

. Solvent less Lamination

· Solvent Base Lamination /Coaters (Wet/Dry)

· Slitters / Rewinders

· Inspection Machine

· Doctoring Machine

· After Printing Guzzeting Machine (Twister/Turn Table type)

· Allied Packaging Machineries

| TECHNICAL SPECIFICATION |

|

|

Type of Machine |

Flexo Printing Press-Stack Type |

|

Series |

Autoflex 2000(*a substitute for Central Impression Machine) |

|

Number of Printing Stations |

4 to 8 colours |

|

Web Width |

500 mm to 1500 mm |

|

Print Width |

400 mm to 1400 mm |

|

Printing Repeat |

350 mm to 800 mm |

|

Printing Possibilities |

Variable as per no of color of machine |

|

Printing Speed |

175 mtrs/min. Maximum Mechanical Speed* |

|

Power Requirement |

Variable as per Machine |

|

Supply Voltage |

415 V,3 Phase, 50 cycles/sec, 4 wire or as required |

|

Floor Space Length /Width/Height |

Variable as machine |

|

Substrate Printable |

LD, LLDPE, HM HDPE, PP CO-EXTRUDED PLASTIC FILMS,POLYESTER BOPP, PVC |

FEATURES• Speed 140 mpm

• 5 Motor Drive tension control system with Programmable digital ac drives

• Hydraulic lift off/on of printing cylinders & Continuous rotation of anilox roll driven by motors

• Inline turn table gussetting system

• Web Video System

• Chambered doctor blade system

• Ceramic anilox rolls

• Silent & powerful drying & exhaust system

• Inline perforation system

Technical Specification:

- Opto Electronic Web Guiding System

- digitally controlled web guiding for precise guiding of web

- Automatic Tension Control System

Load Cell feed back control provided on Unwind, Infeed, Outfeed & Rewind Station to maintain uniform tension throughout the entire roll.

|

5 Motor Drive (5MD) technology for: |

|

1. Unwind Station |

|

2. In feed Station |

|

3. Main Printing Station |

|

4. Out Feed Station |

|

5. Rewind Station |

|

|

Hydraulic System

Provided for continuous rotation of Inking Rollers and Auto Lifting of Plate Cylinders when machine is printing in OFF mode. This prevents drying of inks on the Anilox Roller.

Chamber Doctor Blade System

For uniform & controlled ink supply on the Anilox Roll.

Ceramic Anilox Rolls

Higher mesh laser engraved Anilox rollers for precise transfer of ink to achieve better and enhanced print quality.

Double Diaphragm Ink Pumps

Air operated pumps for controlled circulation of ink between Ink Tank & Chambered Doctor Blade.

Web Video System

Web Inspection System, equipped with high quality color camera, Quick Zoom & Split Screen, mounted on motorised

traverse bar to monitor complete print at all speeds.

Pneumatic Shaft

Provided on Unwind for quick and easy loading and unloading of the Parent roll.

Pneumatically operated Nip Rollers

to maintain uniform & precise tension at printing, infeed and outfeed stations.

Inline Turn Table Gussetting System (Off Set)

to gusset the fabric, inline after printing with turn table system.

Perforation System

for inline perforation on the fabric.

Salient Feature

- · Web guide system

- · Continuous rotation of Inking rollers with hydraulic motors

- · Powerful Exhaust System

- · 5 motor Drive Tension Control System

- · Chambered Doctor Blade System

- · Ceramics Anilox Rolls

- · Ink Pumps

- · Water cool roll on rewind

Technical Specification:

- Opto Electronic Web Guiding System

- digitally controlled web guiding for precise guiding of web

- Automatic Tension Control System

Load Cell feed back control provided on Unwind, Infeed, Outfeed & Rewind Station to maintain uniform tension throughout the entire roll.

|

5 Motor Drive (5MD) technology for: |

|

1. Unwind Station |

|

2. In feed Station |

|

3. Main Printing Station |

|

4. Out Feed Station |

|

5. Rewind Station |

|

|

Hydraulic System

Provided for continuous rotation of Inking Rollers and Auto Lifting of Plate Cylinders when machine is printing in OFF mode. This prevents drying of inks on the Anilox Roller.

Chamber Doctor Blade System

For uniform & controlled ink supply on the Anilox Roll.

Ceramic Anilox Rolls

Higher mesh laser engraved Anilox rollers for precise transfer of ink to achieve better and enhanced print quality.

Double Diaphragm Ink Pumps

Air operated pumps for controlled circulation of ink between Ink Tank & Chambered Doctor Blade.

Web Video System

Web Inspection System, equipped with high quality color camera, Quick Zoom & Split Screen, mounted on motorised

traverse bar to monitor complete print at all speeds.

Pneumatic Shaft

Provided on Unwind for quick and easy loading and unloading of the Parent roll.

Pneumatically operated Nip Rollers

to maintain uniform & precise tension at printing, infeed and outfeed stations.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\