Product Specification

| Brand | DMG MORI |

| Condition | New |

| Warranty | YES |

Product Descriptions

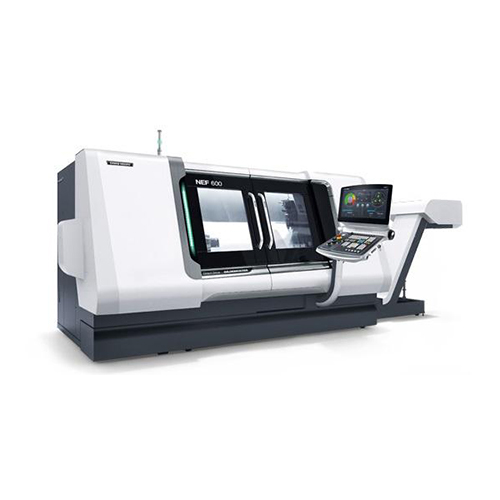

Due to its high-tech components, the new NEF generation makes professional, efficient and precise turning accessible even to the entry-level user. NEF operators benefit from high flexibility for single workpiece manufacturing and achieve maximum precision and dynamics in batch production. Numerous options allow custom-tailored configurations of the machine for maximum productivity in manufacturing. Today’s workpiece production requires a high degree of flexibility. Regardless of whether workpieces are machined as single parts or in small batches, efficiency and precision are top priorities for every order.

Highlights NEF 600

- Integrated ISM spindle motor: Large spindle drillings; higher speeds; better C-axis precision / rigidity; larger bearing diameter for more stability; water-cooled for better thermal stability; service-friendly as belt readjustment is no longer required

- New design: Increased visibility into the working area, optimal ease-of-operation, compact construction

- The latest 3D control technology:

19" ERGOline® with Operate 4.5 on SIEMENS 840D solutionline and ShopTurn 3G or HEIDENHAIN CNC PILOT 640 - Compact design due to a very sturdy, solid cast-iron machine bed

- 12×-station turret VDI 40 with, hydraulically controlled tailstock now included in the standard version

- Drive technology is the best in its class with digital drives for maximum precise precision: spindle true running accuracy in the μ-range

- Traversable steady-rest and tailstock due to a 4-track bed design

- Exclusive DMG MORI technology cycles to save up to 60 % of your time.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\