Product Specification

| Brand | Intralox |

| Condition | New |

| Warranty | YES |

Product Descriptions

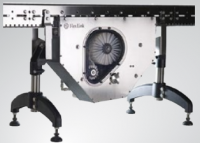

Intralox’s ARB palletizing infeed system provides ultimate flexibility for customized pallet layer forming of the most varied products, at the highest throughput rates. Using Activated Roller Belt™ technology, Intralox’s automated palletizing infeed system includes an ARB Case Turner and an ARB Switch.

The palletizer infeed system provides simple, low-maintenance, automatic palletizing within a small footprint. It precisely arranges packages in a pallet layer configuration, ensuring proper formation; or, it can feed single or dual rows to layer forming robots. Most traditional palletizers can be retrofitted with ARB technology.

Benefits of ARB Palletizing Infeed Systems:

- All the benefits of patented ARB technology

- Create accurate pallet patterns, consistently and reliably

- Will accommodate changing package materials, sizes, and layer patterns with simple controls software modifications only

- Handle products gently, without grippers or bumpers

- Increase worker safety

- Have only one drive and few actuators

Ideal solution for...

- Handling a variety of product sizes (as small as 4 in. x 4 in. [100 mm x 100 mm] with no maximum) and types (cases, tray packs, 2-liter shells, litho-packs, bundles, pouches, polybags, shrink-wrapped packages)

- High-speed palletizing to meet higher throughput rates (225 packages per minute / 10 layers per minute)

- Low-speed palletizing to double the throughput of a robot cell within a small area (25–50 packages per minute / 5–6 layers per minute)

- Creating complex pallet layers or rows of mixed package types and sizes

- Eliminating product damage

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\