產品規格

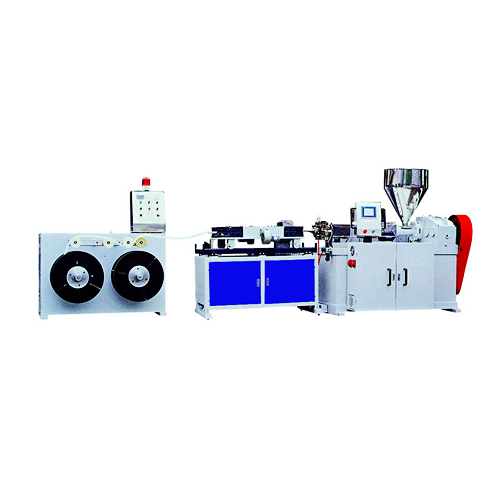

| PE/PP/PVC Single-wall Corrugated Pipe Extrusion Line | |

| New | |

| YES |

Product Descriptions

It is developed by our company based on absorbing advanced German technology. It has advantages, such as, reasonable structure, stable operation, fast forming speed.

Two sizes in one mould for small pipes, can reduce mould cost, reduce the frequency of replacement of moulds and effectively improve production efficiency.

PE,PP, PVC single-wall corrugated pipes can be produced with different extruders.

Specifications:

1.Single screw extruder SJ-65/33

|

Barrel: |

38CrMoAlA under had chrome plating polishing treatment, water-cooling and compulsive material-supplying section |

|

Screw: |

38CrMoAlA under nitrogen treatment |

|

Technical parameter |

|

|

Screw diameter |

65mm |

|

Screw length diameter ratio: |

33:1 |

|

Depth of screw nitrogen layer: |

0.4-0.6mm Hardness:HV>740 |

|

Depth of barrel nitrogen layer: |

0.5-0.7mm Hardness: HV>940 |

|

Barrel heating: |

3-section heating , and cast aluminum heating circle with power of 6kw×5section |

|

Barrel cooling: |

Three section cooling with air. Power of cooling fan is 5section×0.25kw. |

|

Output: |

200kg/h |

|

Reduction gearbox: |

adopts speed reducer of hard tooth surface specially used for extruder |

|

Drive power: |

55kw electrical motor. Speed regulating of frequency control ABB brand |

|

Hopper Dryer & Auto Loader |

|

|

Loading methods: Vacuum |

|

|

Conveying capacity: 300kg/h |

|

|

Motor power: 1.1kw |

|

|

Dryer material: quality aluminum alloy for outside; stainless steel for inside |

|

|

Dryer capacity:100kg |

|

|

Heating power: 7.8kw, heating temperature control automatic |

2. Die head and moulds

|

Die Material: |

Material: quality alloy steel Bolt grade: 12.9 grade high strength bolt Surface of flow channel: Nitriding and polishing treatment |

|

Die head heating: |

1-section heating with stainless steel heating circle |

|

Mould quantity: |

50pairs |

|

Mould perimeter: |

50*65.94=3277mm |

|

Appearance size of mould |

Length65.94*width50*height150mm |

|

Pipe diameter: |

Φ50mm,63mm,75mm,90mm,110mm |

|

Cooling mode:

|

fan cooling, 6 sets of fans, every side have 3 sets, and fan motor power: 0.06kw/set |

3. Pipe forming machine

|

Template quantity: |

1 set, and water-circulating cooling |

|

Template material: |

cast iron |

|

Transmission mode |

gear transmission |

|

Speed reducer: |

2sets of reducer with worm and worm wheel |

|

Cooling mode of the pipe: |

Air cooling. Power of blower is 0.05 kw×4 |

|

Speed: |

1-8m/min |

|

Drive power: |

4 kw electrical motor of frequency control |

|

Counting mode: |

induction counting |

|

Control System : |

|

|

Hardware from French brand |

|

|

Professional software system of XINRONG |

|

|

Menu with English version |

|

|

Human-friendly interface make the operation easily and conveniently. |

|

|

6’’liquid crystal displayer |

|

|

New generation programmable computer control system |

|

|

Modularization of temperature control |

|

|

Operation panel with pellicle switch |

|

|

Equipped with measuring system of melt temperature and pressure. |

|

4. Auto-winding machine |

|

Polish rod type pipe arranging |

|

Single station winder |

|

Winder materials is cast aluminum materials |

|

Drive mode: moment motor. YLJ-5/8 |

使用 Abraa 安全交易系统进行安全可靠的支付

使用 Abraa 安全交易系统进行安全可靠的支付  \

\