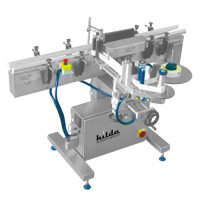

Product Specification

| Mariat | |

| New | |

| Others |

Product Descriptions

The full range of hot-melt rotary labellers is available to apply pre-cut paper or plastic labels on cylindrical or shaped bottles made of glass, plastic or metal.

Features

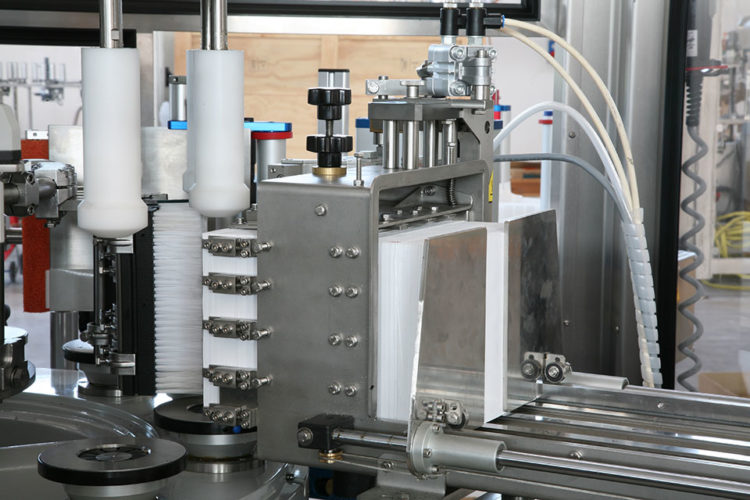

- Hot glue distributed with an industrial sprayer

- The standard equipment of a pre-cut hot-glue labeller includes the machine’s infeed screw operated with a servomotor, quick-release plates operated with a mechanical cam

- The application unit can be fitted with the automatic label storage area

Output range

- Maximum production speed: 30.000 bph

Optional features

- Automatic label storage area

- Plates operated with servomotors

- Electronic orientation system

- Labelling quality control system

- Pressurization system to process empty bottles Laser or ink-jet coder

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\