Product Specification

| Condition | New |

| Warranty | YES |

| Fuel Type | Gasoline |

Product Descriptions

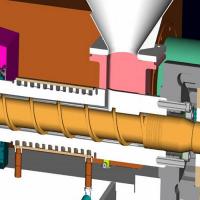

1. Special design of screw, which can ensure material perfect plasticizing and lower formulation cost; Depend on the request of high fill formula,

SKD61(Japan or Germany) imported material with alloy sleeve treatment barrel can provide prefect solution.

2. Co-extruder equipped with dehumidifying and drying system can be applied to produce PMMA/ASA composite material,

which ensures high performance and quality of final product.

3. T-die adopt hanger style can be applied to produce single PVC melt multi-layer material or multi layer compound material.

The mould flow surface adopts polish and electrochromism treatment, which ensure excellent liquidity and good anticorrosion, heat-resisting and

wear resisting performance

4. Distributor mostly applied in multi-layer compound process. It has Several structures

such as A/B, A/B/A, A/B/C and etc. The main purpose is making perfect composition of different melting materials.

5. Calibration forming table includes three parts: calibration mold, haul off and cutter, Forming mould is made of Up and Down moulds,

flow surface adopt polish and electrochromism treatment, which can ensure excellent liquidity and good anticorrosion,

heat-resisting, wear-resisting performance

6. The channel design is S shape to increases contacting surface of mould, which ensures faster heating transfer and quickly cooling

calibration. In order to higher stable hauling, the shape of rubber roller(haul off) designs

according to final product,The cutter adopt sawing type and the shape of blade designs according to

final product, which ensuing flat and chip free cutting

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\