Product Specification

| Condition | New |

| Warranty | YES |

| Fuel Type | Gasoline |

Product Descriptions

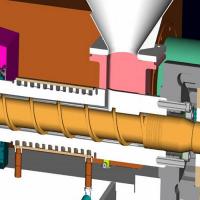

1. Special design of screw, which can ensure material perfect plasticizing and lower formulation cost; depend on the request of high fill formula,

SKD-61(Japan or Germany) imported material with alloy sleeve treatment barrel can provide prefect solution

2. Co-extruder equipped with dehumidifying and drying system can be applied to produce PMMA/ASA composite material, which ensures

high performance and quality of final product

3. T-die adopt hanger style can be applied to produce single PVC melt multi-layer material or multi-layer compound material

The mould flow surface adopt polish and electrochromism treatment, which

ensure excellent liquidity and good anticorrosion, heat-resisting and wear-resisting performance.

4. Distributor mostly applied in multi-layer compound process. It has Several structures such as A/B, A/B/A, A/B/C and etc.

The main purpose is making perfect composite of different melting materials

5. Embosser used for the surface pattern of the roof tile after the calibration mold, which makes glazed tile better out-looking.

6. Calibration moulds usually adopts 18 pairs to 22 pairs cast aluminum modle and each one is composed of bush and mandrel,

completely occlusion, ensures the shape and size of the product, also cooling method adopt frozen cooling air

which greatly improve cooling effect.

7. Cutter with elevator lateral movement functions which ensure smooth and fast cutting;

The clamping rubber block design according to product shape which ensure perfect fitting.

It also avoids product shifting and slippage phenomenon during cutting process.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\