Product Specification

| APINOX | |

| New | |

| YES | |

| Others |

Product Descriptions

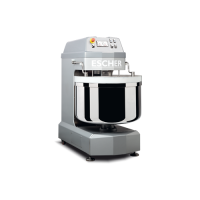

HORIZONTAL MIXER

Our mixer type “RM” is a high speed and high output batch mixer particularly suitable for hard biscuits (tp. Marie – Petit Beurre), soft biscuits, crackers, snacks and/or soft and delicate dough.

The product capacity of the mixer will depend on the recipe and on the degree of automation of the ingredient feeding process.

Our mixer type “RM” differs from the type “IV” in the different tilting system of the bowl, whose larger opening ensures the complete discharge of the dough without the operator intervention.

A conveyor belt for direct discharge of the dough can be positioned under the mixing bowl of our mixer type “RM”, permitting the automation of the working cycle of the mixer and a continuous feeding of the production line.

The advantage of discharging directly the whole dough on a conveyor belt without the operator intervention and not into wheeled tubs enables the elimination of all tilting, lifting and handling devices.

Main technical features:

The shaftless arm is designed to achieve rapid and evenly dispersion of all ingredients and a controlled dough development process.

The elimination of the central shaft improves considerably the discharge, the cleaning and the dough hygiene.

Our mixing arm ensures that the ingredients loaded by hand into any part of the mixing bowl are dispersed throughout the mix rapidly.

The bowl for mixing the product, made out completely in stainless steel, includes a jacket on its whole section for the temperature control.

Bowl tilting to unload the mixed product at over 135° by means of ageared motor and rackwork.

The bowl can be stopped at any tilting position to allow hand feed of minor ingredients.

The mixer chassis is made out of thick electrically welded carbon steel sheets and section bars for heavy duty. The removable panels are made of AISI 304 stainless steel.

High powdered two-speed main motor housed inside the mixer.

The bowl upper part is equipped with a fixed cover fitted with powder-proof gasket to prevent egress of ingredients. It is equipped with ducts according to the customer needs for the feeding of raw materials.

Special attention has been paid to the safety of the operators during design. Apinox mixers are equipped with safety systems to ensure the safety of operators and are in compliance with the rules in force.

The control panel can be installed on the mixer or on the electrical cabinet and can be provided with push-buttons or with touch-screen terminal and PLC.

An important advantage of the apinox mixer is the simple method of construction which makes all parts of the machine easily accessible for maintenance, inspection and cleaning.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\