مواصفات المنتج

| الماركة | Pro-Tech Italia Food Machines |

| الحالة | New |

| الكفالة | YES |

مواصفات المنتج

TECHNICAL CHARACTERISTICS:

Load-bearing structure made of tubular sections of AISI 304 stainless steel.

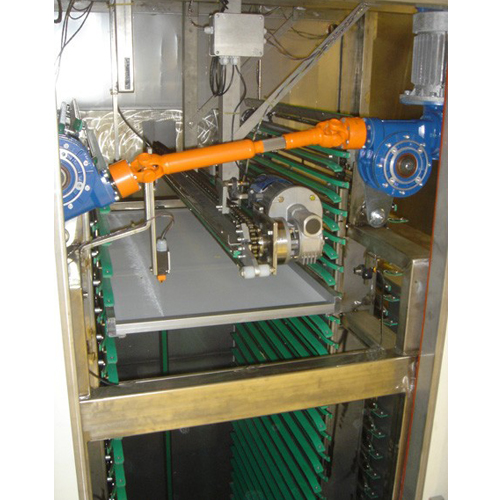

Mechanical drives fitted with motor-reducers with oil-bathed worm.

Insulating panels for high temperatures, made of:

- glass reinforced plastic with internal polyurethane insulation, internal wall fully lined with stainless steel sheet.

- fully made of stainless steel sheet, with polyurethane insulation inside.

- carbon steel sheet, zinc-plated and oven painted, with polyurethane insulation inside.

Panels with quick-opening system.

Ventilation system fitted with axial blowers, with special high-performance fans.

Centrifugal humidity extractor, automatically controlled by the drying control system.

Electrically operated air change valves, operated by the humidity extraction system.

Temperature adjustment by means of automatic valves.

Main switchboard with electronic management of the drying cycles and of the moves through PLC, operational panel fitted with display and keyboard to set the work cycle and to recall drying recipes.

ROTEL is a pre-drying frame system, especially designed to meet the requirements of small pasta factories for the automatic cycle (continuous or discontinuous) production of high-quality pasta, such as: paste nests, tangles, butterflies, short pasta, cannelloni, etc.

The ROTEL system allows treating the just-formed product with temperatures ranging from 60° to 80° C for 20 to 40 minutes, quickly decreasing the humidity of the product; once the pre-drying treatment is over, the product can be sent to the static driers to complete the drying process in accordance with the diagram preferred by the customer.

The pre-drying treatment takes place when the product has a high level of internal humidity, and therefore strong water evaporation keeps the product at a temperature lower than the surrounding air temperature, preserving the organoleptic properties of the raw material.

The use of the ROTEL system ensures many qualitative and hygienic advantages: - General acceleration of the drying process.

- Facilitation of the drying for the formats having higher thickness and complex shapes.

- Possibility of greater loads of pasta on the frames, with subsequent better efficiency of static boxes.

- Reduction of the bacterial charge of the product.

- Block of fermentation process that could increase the acidity of the final product.

- Uniformity of the drying treatment.

- Improvement of the colour of pasta (if extruded through teflon) - Better pasta consistency and cooking characteristics.

- Better mechanical resistance of the dried pasta.

- Better hygiene conditions thanks to frame stacking within a closed, sheltered and heated space.

The ROTEL system consists of the following parts:

- pre-heating tunnel.

- vertical pre-dried.

- automatic frame stacker.

In the pre-heating tunnel, the product is subject to ventilation from below that reduces superficial humidity, sets the product and prevents sticking.

In the vertical pre-drier, the product passes through two separate ventilation zones, where uniform and powerful ventilation reduces humidity up to the envisaged values.

The peculiar mechanical system adopted only requires 2 moves for every frame, guaranteeing high mechanical reliability with minimal maintenance requirements.

The automatic frame stacker is directly connected to the pre-drier, and so the product always remains inside the machine during the frame stacking phase (20 to 40 minutes) without exposure to the outside environment; this will ensure the best possible hygiene conditions.

The stacker is fully lined with insulating panels and is fitted with an independent heating system in order to keep the product under ideal climatic conditions with no loss of humidity.

The automatic stacker places the frames on the cart up to the envisaged number of frames, then an acoustic signal warns the operator that the load is complete and that it is necessary to replace the loaded card with an empty one.

Thanks to the minimal number of passages and to the lack of mechanical stresses applied to the frames, the ROTEL system allows using both wooden and aluminium frames with full reliability.

Depending on the products, the ROTEL line is realised with the following frame sizes:

- 600 x 1200 mm, made of wood or aluminium

- 1000 x 1400 mm, made of aluminium

طريقة دفعة آمنة وموثوقة باستخدام منصة عبرة للدفع عبر الانترنت

طريقة دفعة آمنة وموثوقة باستخدام منصة عبرة للدفع عبر الانترنت  \

\