Product Specification

| Brand | Francis |

| Condition | New |

| Warranty | YES |

Product Descriptions

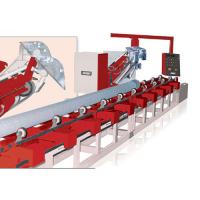

FWB supplies sand cast items in heat, wear and corrosion resistant alloys up to 35kgs. Castings are manufactured at our sister company, J. T. Price, on our new semi-automatic moulding carousel and core-blowing platform, which was installed in September 2013. This represented a £1M investment to create a highly-resourced platform for the long-term supply of copper and nickel based sand castings.

The installation has resulted in a streamlined, semi-automated moulding process providing numerous benefits for our customers:

Diversity of volume

- Ability to manufacture high volume production runs, but also produce 1 offs/samples/prototypes if required

- Flexibility to reduce or build volume to suit demand

- Large melting capacity from a dedicated suite of electric induction furnaces

- Capacity to produce 250 to 300 moulds per day on a basic shift

Responsive lead times

Increased productivity and efficiency means responsive delivery times and the flexibility to accommodate urgent break-down orders

Geometrical casting production

New generation gassing technique to create cores with superb surface finish, excellent adherence to geometric tolerances, and cores of very high strength

Patterns are able to be made or modified in our in-house pattern shop

Flexibility of supply

Castings can be supplied unmachined or our customers can benefit from our in-house finish machining and assembly service at Francis W Birketts

Full traceability

Laboratory investment and upgrade enabling metallurgical spectrographic control of every melt and compliance with PPAP/PED

Greener process

Sand reclamation through primary and secondary attrition lessens the environmental impact

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\