Product Specification

| Brand | PRISM |

| Condition | New |

| Warranty | YES |

| Year Model | 2017 |

Product Descriptions

|

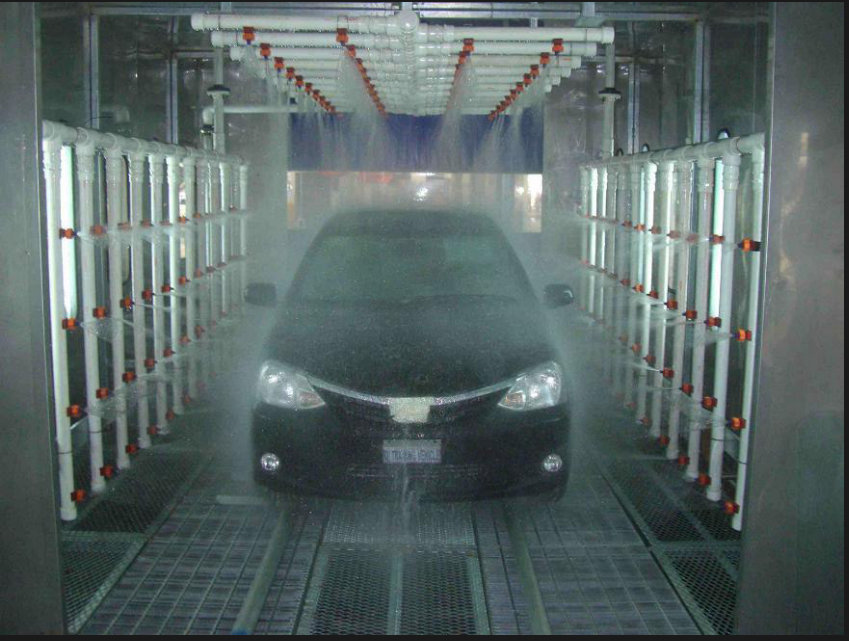

In today’s globalisation era where quality is the prime criteria, car and bus manufacturers are not willing to compromise on their production method. High standards for safety have to be ensured for each unit produced. The government is contemplating to make it compulsory for all car bus and truck manufacturers to have a shower tester booth in thier production line to test for water seepage or to make sure water doesn’t enter the vehicles. Prism is now helping car and bus manufacturers to install these shower/water tester booths for the automotive industry. |

|

|

The primary motive of a why a shower tester booth is built is to make sure or test whether water will enter the particular vehicle or component and identify where the leaks are. Subsequently, the leakage areas have to be plugged. Every vehicle needs to be ensured that there is no leakage / seepage in rains. This shower tester booth uses high pressure nozzles where water hits the surface at high pressures to test whether water enters in or not. Water from the booth is also filtered and recycled. Prism also supplies an air shower booth for quick drying of external surface to facilitate immediate inspection. The air shower booth consists of blowers that blow air at high velocity through air nozzles. In the air drying booth Special air knives are used to remove water and dry the surface quickly. Different programmes can be tailor made to automate the entire process from opening of door to allow vehicle inside to roll out the vehicle out of the air shower booth. According to the clients requirement various levels of automation can be introduced. |

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\