Product Specification

| Brand | AKW |

| Condition | New |

| Warranty | YES |

| Mechanical Condition | Excellent (No problems or history of failures) |

| Fuel Type | Electric |

Product Descriptions

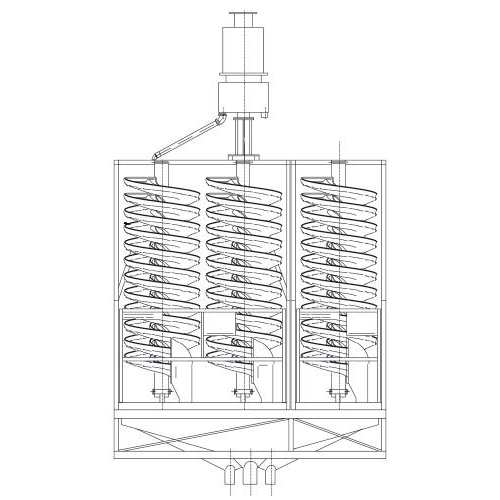

Spirals AKA-SPIN

Spirals are sorting devices which separate the materials according to their different densities. They can be used for a grain size range from approx. 0.04 mm to 4 mm, with a throughput per spiral of approx. 1–4 t/h. If a higher throughput is required, 2 or 3 spirals can be combined to form one column. Several spiral columns can be joined to form banks of 2, 4, 6 or 8 with one distributor for the inlets and collector chutes for the outlets. Different types of spirals for heavy, middling and light density products.

Principle of operation

The slurry (content 10 – 40% solids depending on application) is fed into the spiral from the top. Spread on the spiral bottom, it moves down by gravity. A transverse flow is directed inwards on the sluice bottom or outside on the slurry surface is superimposed on the main flow. This combination results in a separation of the particles contained in the suspension, depending on their density. Particles with a lower specific gravity, such as wood, coal or organic matter, are concentrated in the outer areas of the flow. Particles with a higher specific gravity are transported towards the spiral axis.

Design features and advantages

- Separation of lightweight fraction by force of gravity

- Separation of heavy minerals from quartz sands

- Separation of up to 3 fractions: heavy, middling and light density products

Applications

- Sorting of ores and minerals

- Coal processing

- Decoaling of construction sands

- Soil remediation by soil washing

- Processing of municipal waste

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\