| Salient Features |

| • |

Fulfills storage conditions of 25°C – 60% RH, 40°C – 75% M RH, 30°C – 65% RH, 25°C – 40% RH |

| • |

Precise monitoring of temperature and humidity conditions |

| • |

Unique design of thermal barrier for better energy efficiency |

| • |

Machine filled PUF insulation to eliminate void pockets |

| • |

Powerful fan motor for forced air circulation to maintain uniform conditions inside chamber within permissible limit Heating by long life SS tubular heaters |

| • |

Hermetically sealed Compressor with CFC free refrigerant |

| • |

Chamber calibration port on side |

| • |

Adjustable trays |

| • |

Output for remote alarm |

| • |

Microprocessor controller with LCD display & capacitance type sensor |

| • |

4 " attractive LCD display for direct display of humidity & temperature |

| • |

Auto tuning of controller |

| • |

Battery Backup for Controller |

| • |

Settable High / Low alarm points |

| • |

Centronic interface to record temperature, Humidity, Date & Time by attaching Dot Matrix printer with adjustable print interval |

| • |

REMI ‘Datasoft' data acquisition software complying to 21 CFR part 11 as per USFDA Guidelines (Optional) |

| • |

Power failure and resumption recorded with date and time |

| • |

PC communication through RS – 485 with data acquisition software |

| • |

High temperature safety cut off & alarms for high/low set parameters |

| • |

Low water level alarm and power cutoff of boiler tank heater |

| • |

Time delay for compressor switch on |

| • |

Overload cut off relay for compressor |

| • |

Rounded inner chamber for easy cleaning |

| • |

Auto door closer |

| • |

Attractive door profile |

| • |

Data logger for 8 point (4+4) temperature / humidity recording with sensor, printer interface and software (Optional) |

| |

Optional |

| |

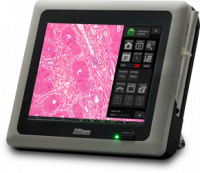

(i) |

Touch screen display ( TFT ) with additional features(Details overleaf) |

| |

(ii) |

Validation protocol with IQ, OQ, PQ Documentation |

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\