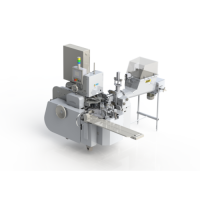

Product Specification

| Condition | New |

Product Descriptions

FEATURES

Automatic Material SupplyMaterial supplied in space-saving rolls and replaced automatically when empty

Since the carton blanks are made inside the machine, customers can enjoy all the distribution and storage efficiency advantages of roll fed packaging material. When empty, the packaging material reels and strips are replaced automatically, so there's no need to stop the machine to refill.

Sleeve FormingEnables the packages’ unique bottle shape

Inside the machine, the packaging material is cut into blanks to make individual packages. These are then wrapped around a mould and sealed to create the sleeve. This method of forming gives a consistent and accurate shape, to which the package's unique bottle-shaped top can be applied.

Integrated lid-formingForming a unique shape and saving space in production

Injection moulding technology is used to create a top, fusing together the carton sleeve with the capped neck to a ready to fill package. Since this function is integrated into the machine, it also saves space in your production hall.

Aseptic ChamberThree-step process ensures sterility of the package

The package is sterilised in the aseptic chamber in three steps. First the package is pre-heated, then treated with hydrogen peroxide gas, and finally ventilated with sterile air to eliminate all the gas in preparation for product filling.

Distance FillingFour-step filling process minimises foaming

The sterile package enters the Distance Filling section of the machine where it is filled with product in four steps, thus minimising foaming. Since the system has few moving parts, the air flow is not disrupted, leading to a reliable, high quality filling process.

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\