Product Specification

| Brand | AKW |

| Condition | New |

| Warranty | YES |

| Mechanical Condition | Excellent (No problems or history of failures) |

| Fuel Type | Electric |

Product Descriptions

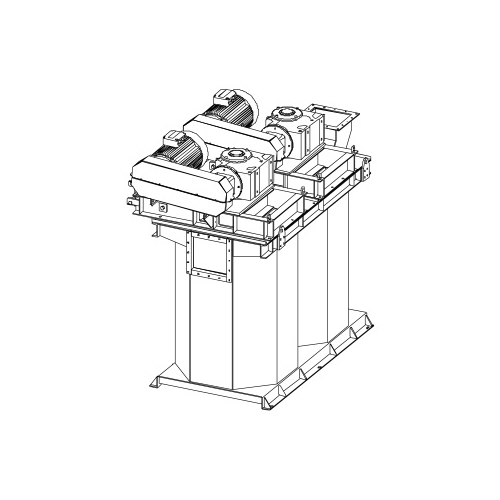

High Performance Attrition Cells AKA-TRIT

The attrition process is used for cleaning raw and residual materials contaminated with adsorbed impurities or pollutants. In this process, the individual particles are stirred intensively in high-solid slurry, which causes any adherent pollutants or extremely fine particles to be rubbed off the particle surfaces. The patented high-performance attrition system of AKW Apparate + Verfahren GmbH enables a consistently effective attrition even under fluctuating inlet conditions

Principle of operation

In a high performance attrition the process conditions can be selectively adjusted during the attrition by means of on-line measurement of the solids concentration and controlled recirculation of an already cleaned flow of coarse material or the addition of diluting water. The efficient measuring and control unit warrants that the attrition conditions are reliably maintained for the entire duration of the process and thus creates the preconditions for an effective cleaning action of the attrition process.

Design features and advantages

- Tank with vertical agitator and V-belt drive

- 2-, 4- or 6-cell construction with chamber volume each cell 0.5 m³; 1.0 m³; 2.0 m³; or 3.0 m³

- Robust, wear-resistant and low-maintenance construction in steel/stainless steel with easily replaceable wear protection (rubber/PU) for tank and agitator

- Computer-controlled, defined solids concentration

- Connection to existing plant control system is possible

- Retrofitting of existing attrition plants for high-performance attrition is possible

Applications

- Processing of ores, minerals and mineral raw materials

- Wet mechanical purification of contaminated soil components

- Conditioning of raw sand

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\