產品規格

| WRAPTECH | |

| New | |

| Others |

Product Descriptions

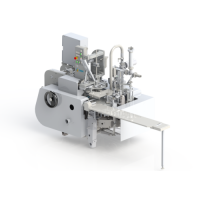

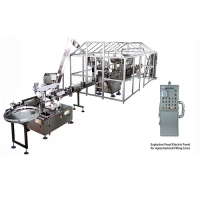

A vertical form, fill and seal machine for producing centre sealed sachets handling all types of free flowing/non-free flowing powders/granules.

The model MB-20 handles a single reel film stock. Max. reel width is 300 mm on 76 mm core. The machine has the facility to be provided with a variety of filling heads. Draw down of the film is through puller wheels controlled through a Electromagnetic Clutch Brake Combination. The length of the bag is controlled by print registration system which is PLC based. For unprinted film, the bag length can be adjusted from the single touch key pad provided on the front panel.

Product Range

| Free Flowing Granules, Powders,Pulses, Rice, Rava, Sugar, Glucose,Salt, Detergents, Tea,Coffee Beans, etc. | Ground Spices, Milk / Chocolate Powders,Ground Coffee Powders, Soup Mixes, Non-free Flowing Pharmaceutical and Agricultural Powders,Pesticide Powders, etc. |

Filling Range

From 1 gm to 250 gms depending upon bulk density of products & the fill weight the maximum pouch size can take.

Output

Up to 60 packs per minute depending on product flow properties and pack size

Pack Size

Width: From 30 mm to 140 mm

Length: From 70 mm to 200 mm

Special Features

- FFS Machine with Intermittent Motion • PLC based Control with MMI

- Puller Wheels with Clutch Brake Control • Pneumatic Actuated Horizontal & Vertical Jaws

- Tool-less Roll Unwind

Packaging Materials

The machine will accept most types of laminated films up to maximum of 300 gauge. It is important that the sealing medium incorporates the best possible slip characteristics. Pure unsupported polyethylene film may be used with special impulse sealing equipment.

Electricals

| • | Power Input | 3 Phase 415 V AC, 50 Hz |

| • | Motor | 0.5 to 1.0 HP, 3 Phase 415 V Motor, Options : VFD Controls |

| • | Heaters | Cartridge type 300 w x 3 pcs |

| • | Temperature Controller | Digital Temperature Controller with FEK Thermocouple |

| • | Fully automatic photo cell control system |

Dimensions & Weight

| Floor Area | 1000 mm x 1600 mm |

| Height | 1900 mm with Hopper |

| Nett Weight | 400 kgs |

| Air | 5.5 kg/cm2g |

Optional Extras

Take off conveyor, batching device, coding, perforator between sachets, over-printing attachment, gas flushing and infeed product elevator system.

使用 Abraa 安全交易系统进行安全可靠的支付

使用 Abraa 安全交易系统进行安全可靠的支付  \

\