Ürün Özellikleri

| WRAPTECH | |

| New | |

| Others |

Product Descriptions

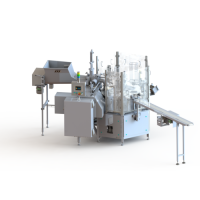

A vertical form, fill and seal machine for producing centre sealed sachets handling all types of free flowing / non-free flowing powders / granules.

The machine speed is infinitely controlled from 20-70 cycles/ minute. Actual speed depends upon laminate and product.

Single reel film laminate stock reel feed. Max reel dia. 400 mm on 76 mm core ID. Product dosing by cup filler. All parts in contact with product are made of high quality stainless steel.

Sealing dies gear operated. With complete pressure and temperature control on sachet seal area.

Filling Range

From 0.5 gm to 25 gms or

From 25 gms to 100 gms depending upon bulk density of the product

Output

20 to 70 packs per min depending upon flow characteristics of products and pack size

Product Range

| Cup Filler | Detergents, Pharmaceutical and Agricultural Powders / Granules, Tea, Tobacco, Pan Masala, Coffee, Snack Foods, Farsans and Namkins |

| Auger Filler | Powders / Granules, Spices, Soup Mixes, Pharmaceutical and Agricultural Powders / Granules |

Pack Size (Extended size on request)

Width from 35 mm to 120 mm or 80 mm to 150 mm

Length from 50 mm to 120 mm or 90 mm to 240 mm

Specifications

A robust machine with particular consideration for minimum maintenance and ease of adjusting and giving high reliable output. All parts in contact with product, manufactured in stainless steel. Accurate sealing die temperature control and fully controllable die pressure. Cut off blades for separating sachet from film web housed in horizontal die for maximum efficiency. Photo cell print registration. Comprehensive push button control panel with cycle counter. Front safety guard and access door electrically interlocked (Optional). Tool kit and Operator Manual supplied with the machine.

Pack Data

- Telescopic, adjustable cup filler provided to take up variations in product bulk density

- Change parts such as collar, cups, gears needed for size change

- Centre seal with crimp pattern / line pattern

- Uses any heat sealable laminate or film

- Centralised lubrication system

Electricals

| Motor | 0.5 HP, 415 V AC driven through VFD or 0.5 HP, 230 V single phase, 50-60 Hz |

| Heaters | 150 w x 2 pcs, 350 w x 2 pcs |

| Temperature Controller | Temperature controller with FEK thermocouple |

| Fully automatic photo cell control system |

Dimensions & Weight

| Floor Area | 750 x 600 mm |

| Height | 1750 mm |

| Nett Weight | 380 kgs approx. |

| Gross Weight | 450 kgs when packed in one case |

Optional Extras

Take off conveyor, batching device, tear-cut device, coding, perforator between sachets, over-printing attachment and gas flushing, infeed product elevator system, auger filler.

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler

Abraa güvenli ticaret sistemlerini kullanarak güvenli ve emniyetli ödemeler  \

\