Product Specification

| Brand | WRAPTECH |

| Condition | New |

| Material | Others |

Product Descriptions

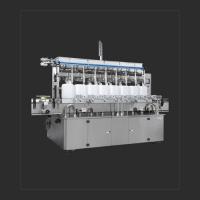

A vertical Form, Fill and Seal machine for producing 4-side sealed sachets handling all types of free and non-free flowing powders / granules, liquids, creams or pastes.

The machine speed is indefinitely controlled from 0-50 cycles / minute. Single reel film laminate stock reel feed.

Filling Range (Depending upon bulk density of the product)

| For Powder & paste: From 0.5 gm up to 30 gms | For Liquids: From 1 ml up to 100 ml |

Output (Depending on product flow properties & pack size)

Up to 300 per minute

Pack Size (Extended size on request)

Width: from 40 mm to 65 mm;

Length: from 50 mm to 150 mm

Max. Foil Width

800 mm

Dosing Options to suit product requirement :

| (a) Slide Filler Unit (SF) | Pneumatic actuated Slide Filler unit with common Hopper, suitable to dose free flowing powders / granules like ORS powders, various free flowing Pharma Powders, Granules, Sugar, Salt, etc. Motorized Stirrer in the common Hopper or vibratory feeder between the Hopper & Slide filler can be offered as optional items. |

| (b) Servo-driven Auger Filler Unit (AFS) | Independent Servo-driven Auger Screw for each lane with, motorized stirrer and Common hopper with agitator. Unit is suitable to dose non-free flowing sticky powder like, Milk, Turmeric, sticky pharma powders, etc. |

| (c) Electric Motor-driven Liquid Filler Unit (LF) | Electric Motor-driven independent Volumetric Syringe pump per each lane with system for Suck-back, adjustable volume and speed. Unit is suitable for dosing liquid products like, shampoo, cough syrup, coconut oil, liquid detergent, ketch up, etc. |

| (d) Electric Motor-driven Viscous Paste Filler Unit (VPF) | Motor-driven independent Volumetric Piston Block pump with Positive tail cut-off system per each lane, with system for adjustable volume and speed, Common / individual Jacketed Hopper with motorized stirrer. Unit is suitable for dosing viscous paste products, like Tomato paste, Peanut paste, Jellies, cream, Chocolate paste, etc. |

Features

A robust machine with particular consideration for minimum maintenance and ease of adjusting and giving high reliable output. All parts in the contact with product, manufactured in stainless steel. Accurate sealing die temperature control and fully controllable die pressure. Cut off blades for separating sachet from film web housed in horizontal die for maximum efficiency. Photo cell print registration. Comprehensive push button control panel with cycle counter. Front safety guard and access door electrically interlocked (Optional). Tool kit and operator manual.

Power drive for Film pull

0.75 KW, 415V Servo drive with synchronous motor

Electricals

- Heaters: 300 W each

- PID temperature controller

- Fully automatic photo cell control system

- PLC controls with integrated HMI

Out-feed Conveyor

Driven by Geared 0.37 KW, 220 Volts, 3 phase AC motor

Compressed Air

500-850 lpm at 6 kg/cm2 g

Dimensions & Weight

| Floor Area | 1350 mm x 1650 mm |

| Height | 2450 mm |

| Nett Weight | 800 kg approx |

| Air | 1000 kg when packed in one case |

Optional Extras

- Out-feed Conveyor with String folding feature

- Tear-cut or V-Notch Device

- Emboss Coding

- Batch Printer

- Perforator between Sachets

- In-feed inclined screw conveying system with ground level hopper

Safe and secure payments using Abraa safe trade systems

Safe and secure payments using Abraa safe trade systems  \

\